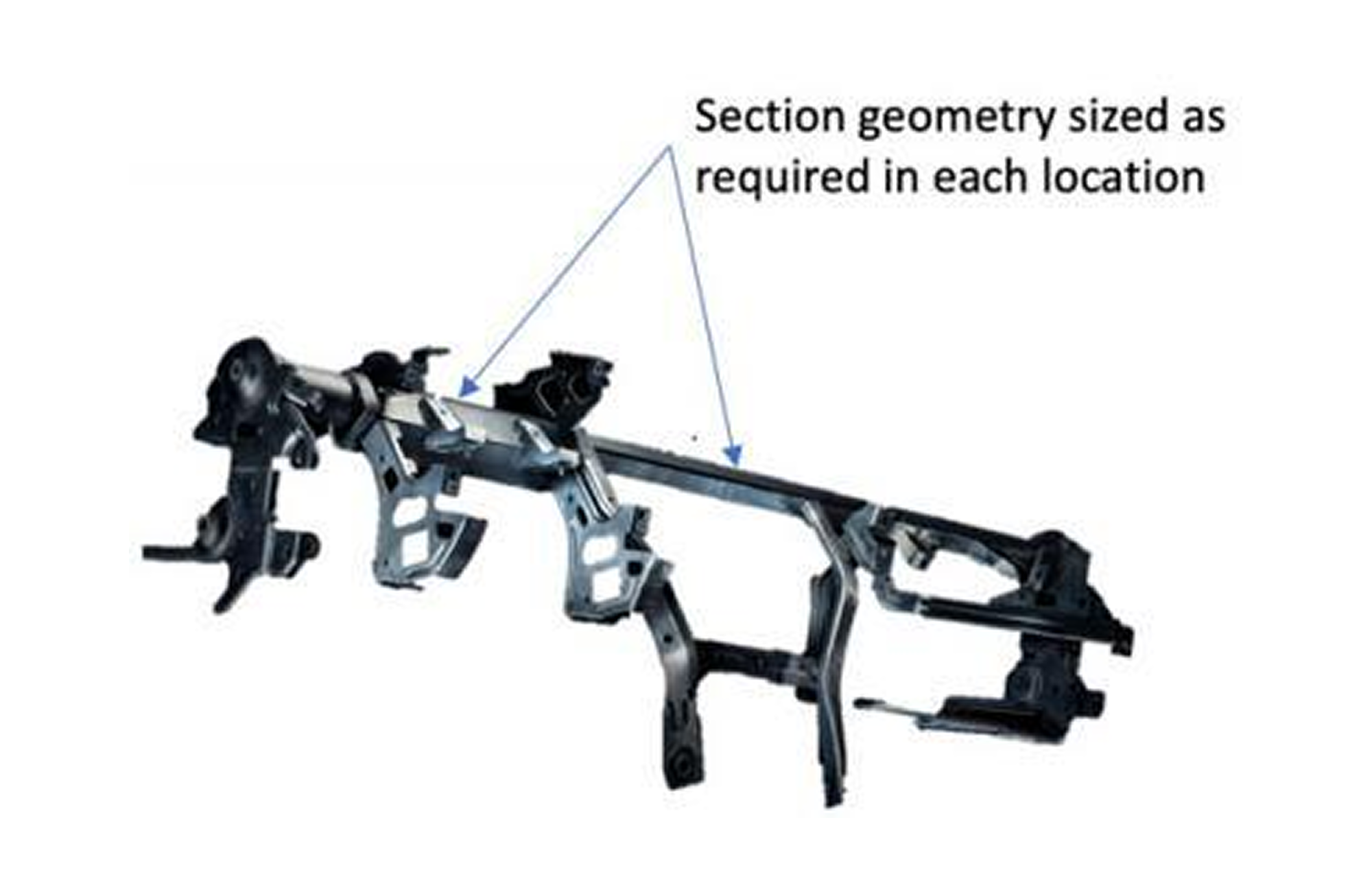

Extrusions provide multiple advantages for cross car beams

- Crash management

- Low vibration structure, particularly important when supporting massive user interface touch screens

- Lower weight than steel or magnesium

- Low tool costs; easy to produce LH / RH models

- Quick to market with short tooling lead time

- Ease of joining and assembly

Select the vehicle below to learn more.

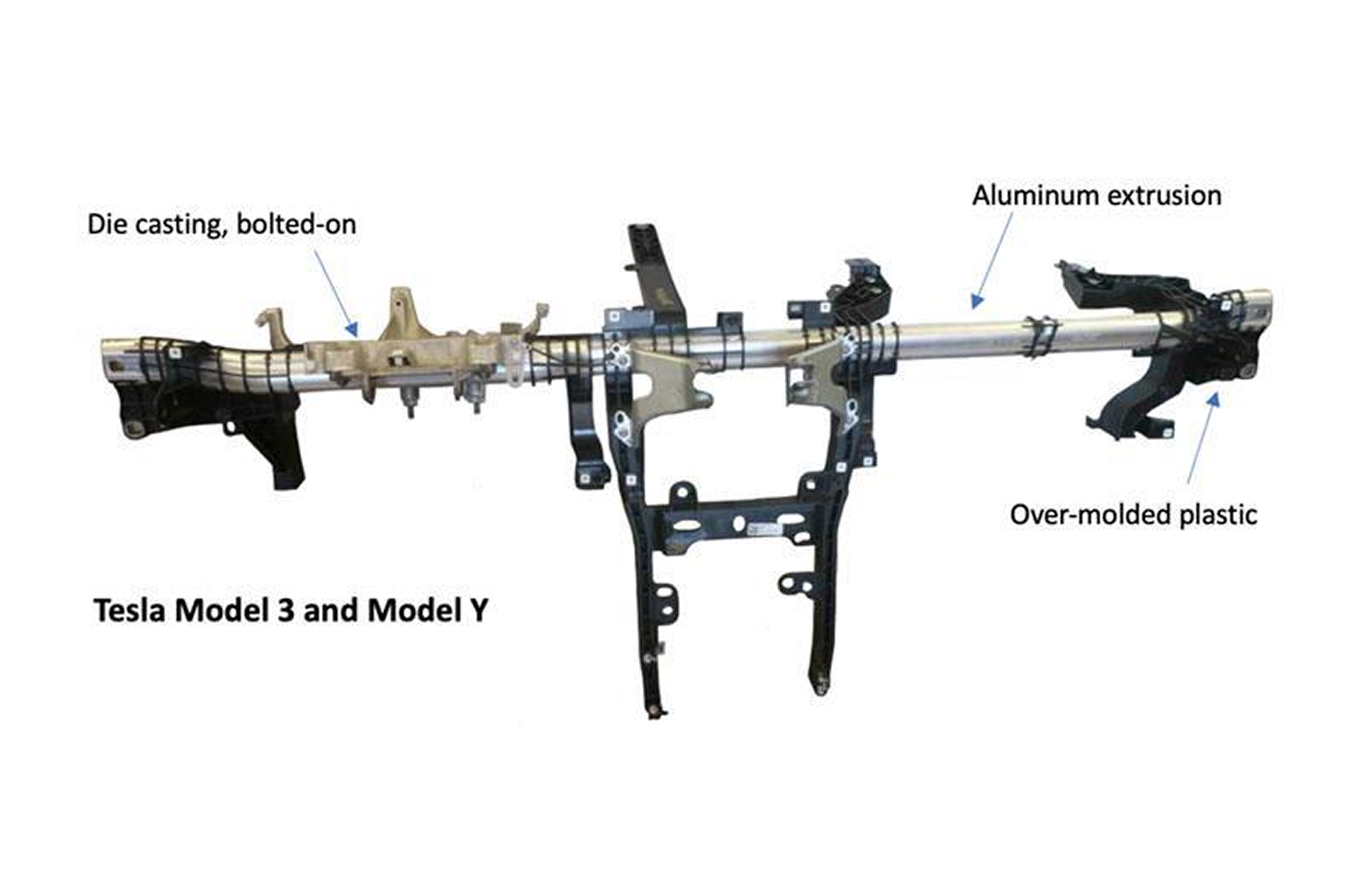

Tesla Model 3 & Y

Novel design utilizing an aluminum extrusion as the central structure, with over-molded plastic and bolted-on castings in support areas.

Tesla Model S & X

Cadillac CTS V-Sport

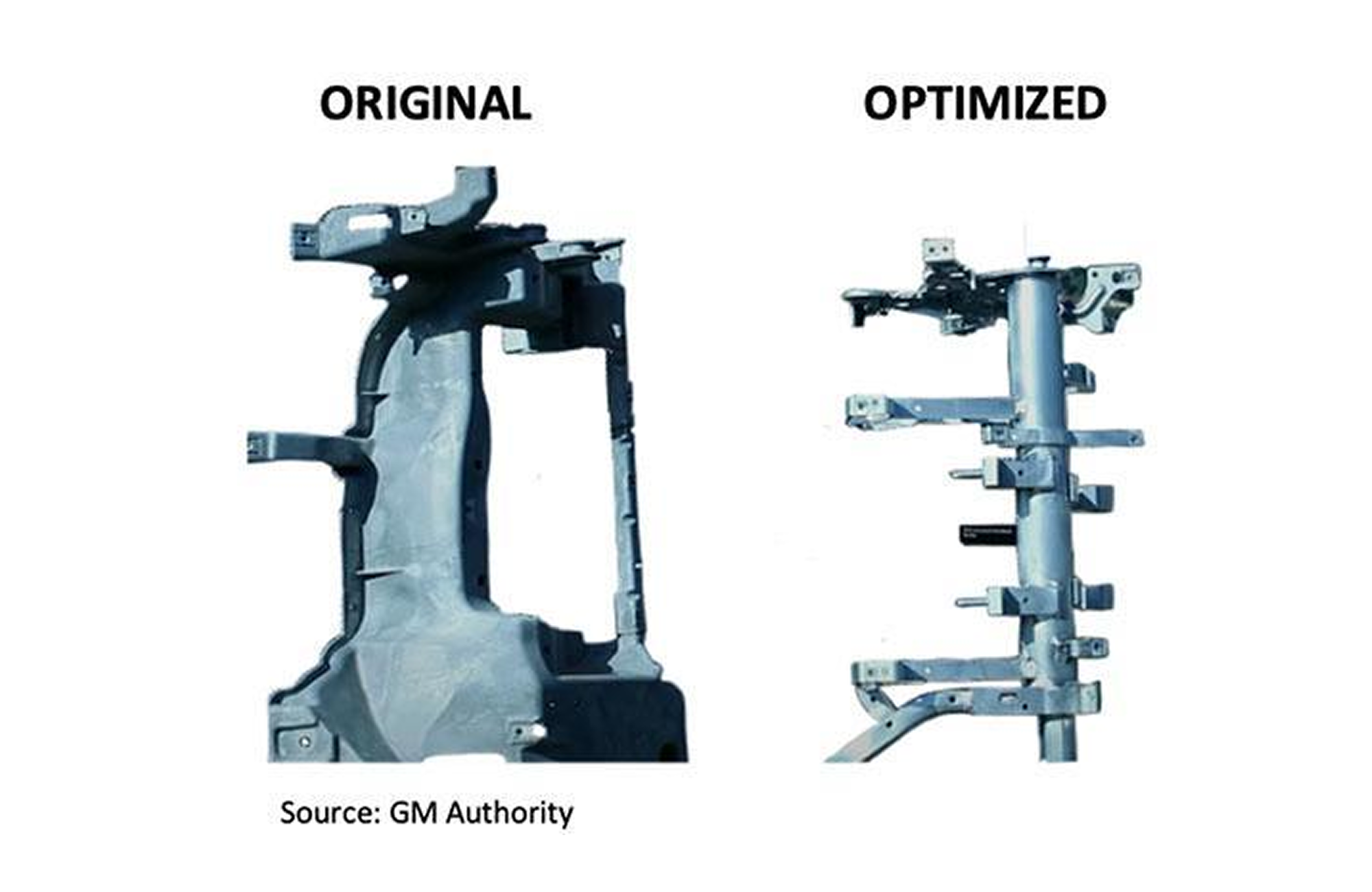

Original: Magnesium die casting: 21.6 lbs (9.8 kg)

Redesign: Aluminum extrusion assembly: 14.4 lbs (6.5 kg) = 36% weight reduction

Aluminum Advantages over Magnesium

- 30% higher material stiffness

- Reduced weight by utilizing material where product performance value exists

- Reduced tooling, for LH / RH designs

- Quick, production-like prototypes

- Multi-material; best material in optimal location

- Tight profile tolerances over long length

Source

2018 Chevy Camaro

Chevy Bolt

2019 Acura NSX

Ready to get started? Find an extruder