Aluminum Extrusion Design Tips

Aluminum extrusion offers designers freedom from “standard” shape restrictions that is unrivaled among structural materials. With aluminum extrusion you can design exactly the shape you need, putting metal only where you need it and let the production process accommodate itself to your design. Careful design is the way to gain maximum benefit from the many valuable characteristics of aluminum alloys and the flexibility of the extrusion process.

Shape Configuration

The designer’s first priority is to satisfy a specific need. Aluminum Extrusions can be designed to aid in assembly, improve product appearance, reduce or eliminate forming and welding operations, and achieve many other purposes. Basically, aluminum extrusion allows you to design the shape that best meets your functional, structural, and aesthetic requirements.

Extruded shapes are described in three general categories: solid, hollow, and semi-hollow.

Extrusion Design Guidelines

Here are some tips to help you better design a profile for the best cost and process efficiency.

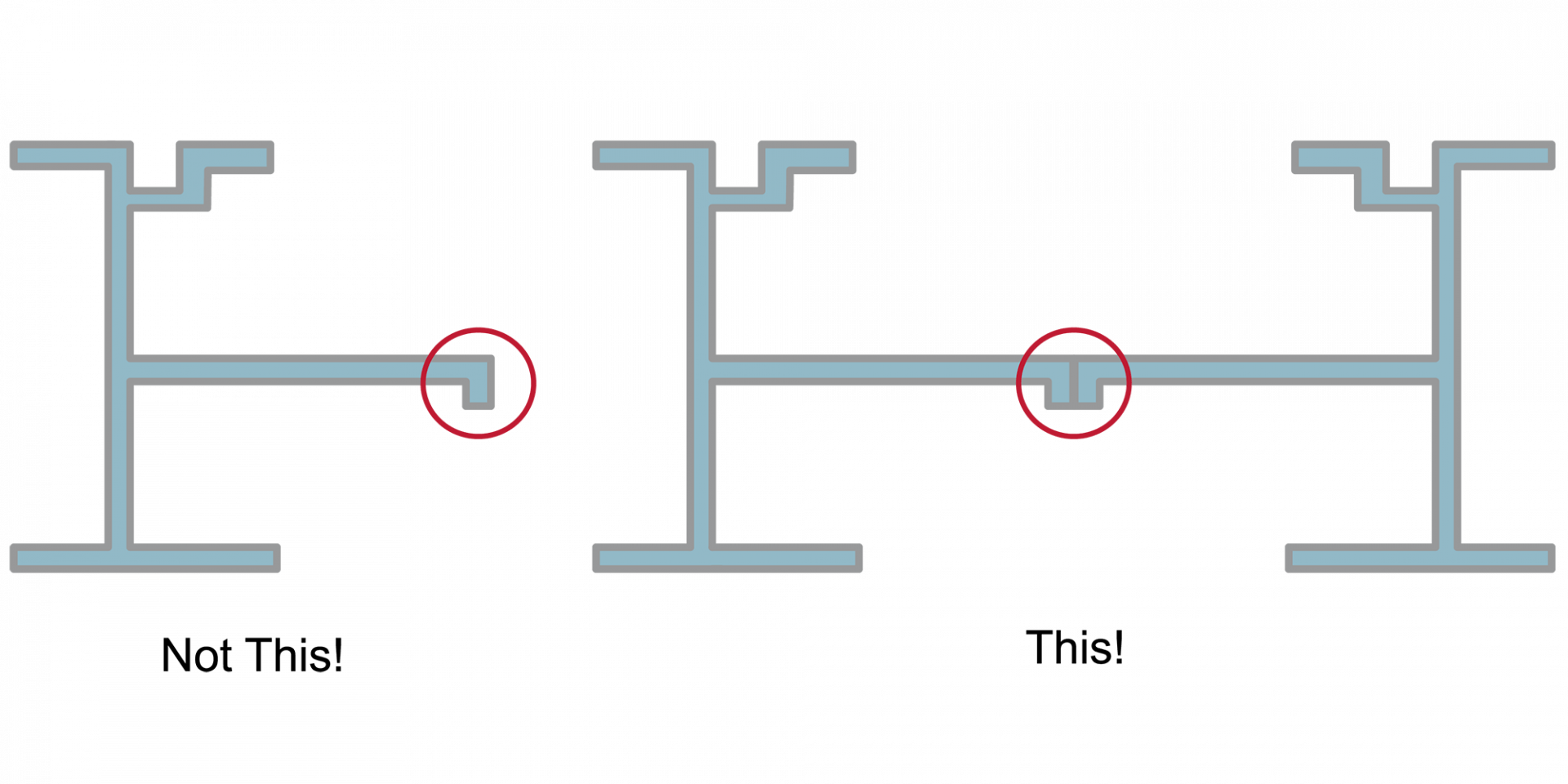

Smooth All Transitions

Transitions should be streamlined by a generous radius at any thick-thin junction. Also, avoid knife edges by rounding sharp corners and providing generous tapers. Inside corners should be a minimum of .015”. Change the profile to blunt of rounded point. If a sharp corner is needed, consider a corner relief.

Enhance Visual Surfaces

Use grooves, webs, and ribs. Wide, thin sections can be hard to straighten after extrusion. Ribs help straighten operation, reduce twisting, and improve flatness. With a little extra effort or cost, designers can add grooves, ridges, or other decorative detail. Shallow groove marks make drilling, punching, and assembly easier by eliminating the need for center punching. Index grooves can also be used to help identify pieces that are similar in appearance, or to distinguish an inside vs. outside surface.

Note: The design tips presented above should be viewed as guidelines to optimize process efficiency. Complex profile designs, which violate many of these guidelines, are also possible and may lead to the most appropriate solution. Discuss your needs with a qualified extruder who can help determine the best overall design.

For more information on aluminum extrusion design:

Key Design Considerations Integrating Functionality Tolerances Fabrication Finishing Functionality

Aluminum Extrusion Manual

Many more design tips are available in the AEC Aluminum Extrusion Manual.

Ready to get started? Find an extruder