Extrusion Applications in Machinery

Aluminum extrusions provide solutions for a diverse range of machinery and equipment needs. The ability to execute complex shapes, combined with its light weight, high strength, and low maintenance properties make extrusions essential components of equipment ranging from conventional mechanical drives to state-of-the-art equipment.

Factory Automation

In factory automation, extrusion are found in actuators, linear motion components, and robotics due to their precision, low mass, high strength, and low maintenance. You'll also find wide use of "erector set" systems in the workplace. These systems are often T-slot profiles that can be combined with special hardware to create machine guarding, run-out tables, factory workstations, and more.

Flexible Applications

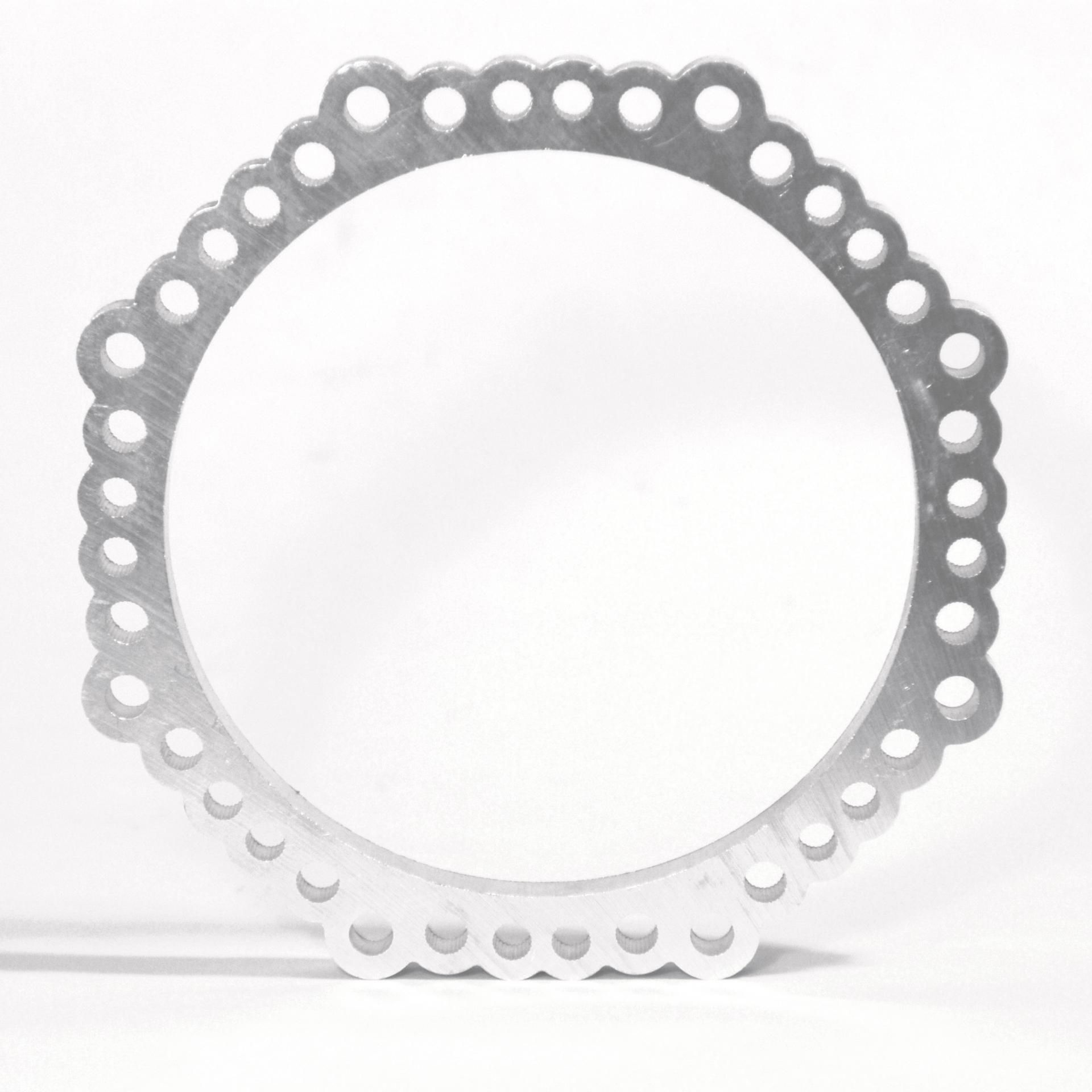

You'll also find extrusions' design flexibility employed to create solutions in a multitude of scientific, medical, and technical equipment. One of the parts above helps control the light beams used for particle physics research at one of the US National Labs. Another is a key element in a home oxygen concentrator, used to concentrate the oxygen in household air for those with respiratory problems.

The Big Chill

Aluminum extrusions are ideal for cold applications, as well, due to aluminum’s high thermal conductivity, cryogenic strength, and ability to perform in harsh environments. This small section of a longer extruded heat exchanger incorporates various functions. The extrusion process is the only viable technology to cost effectively fabricate a part of this type.

Ready to get started? Find an extruder