Protecting Occupants

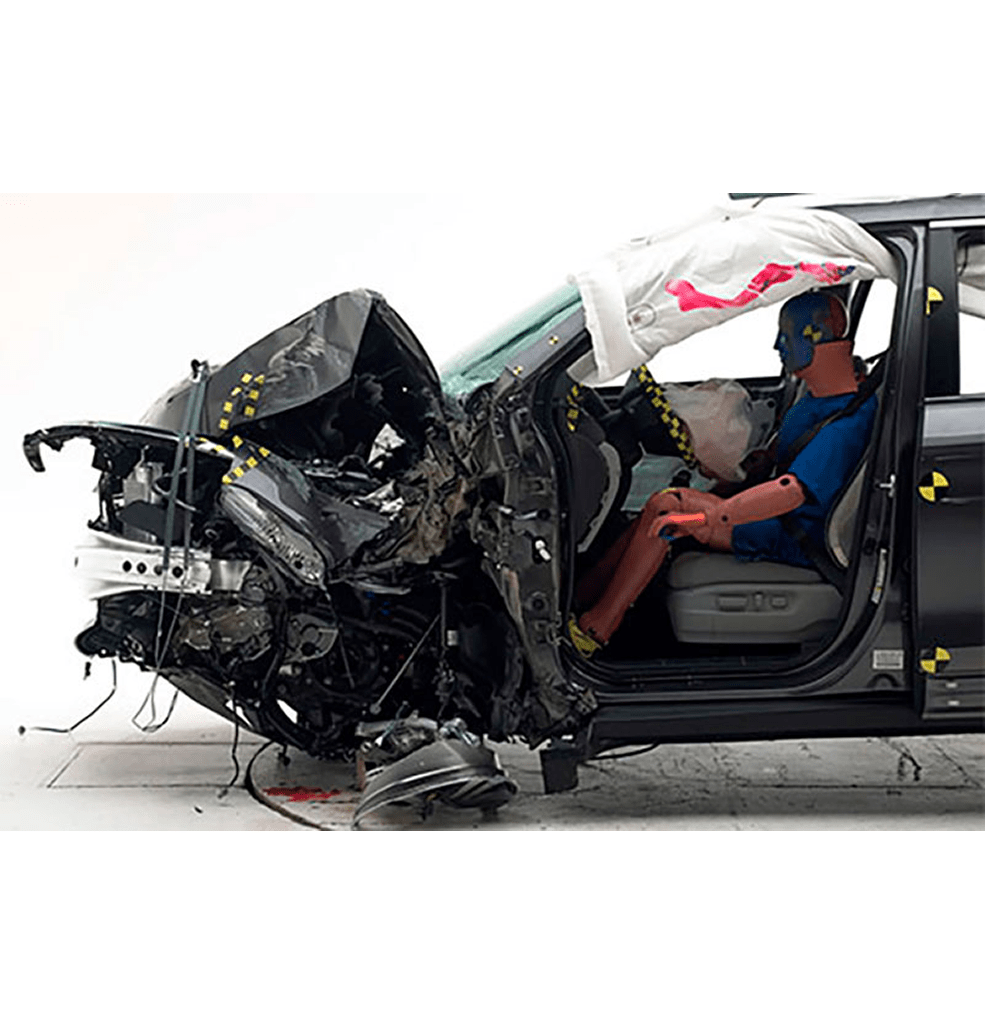

Passenger vehicles come in many shapes and sizes, yet they have at least one thing in common: they need to protect the occupants in an accident. Vehicle manufacturers design and test for a number of crash scenarios including front, rear, and side impact and roll-over. The goal is not to prevent vehicle damage; instead, it is to design the body structure to absorb or deflect energy to protect the passenger compartment.

Crash Management

The governing body in North America is the National Highway Traffic Safety Administration (NHTSA), along with the Insurance Institute for Highway Safety (IIHS), which does extensive testing because of coverage of accidents by auto insurance companies. IIHS evaluates a vehicle's crashworthiness with the help of six tests: moderate overlap front, driver-side small overlap front, passenger-side small overlap front, side, roof strength, and head restraints & seats.[1]

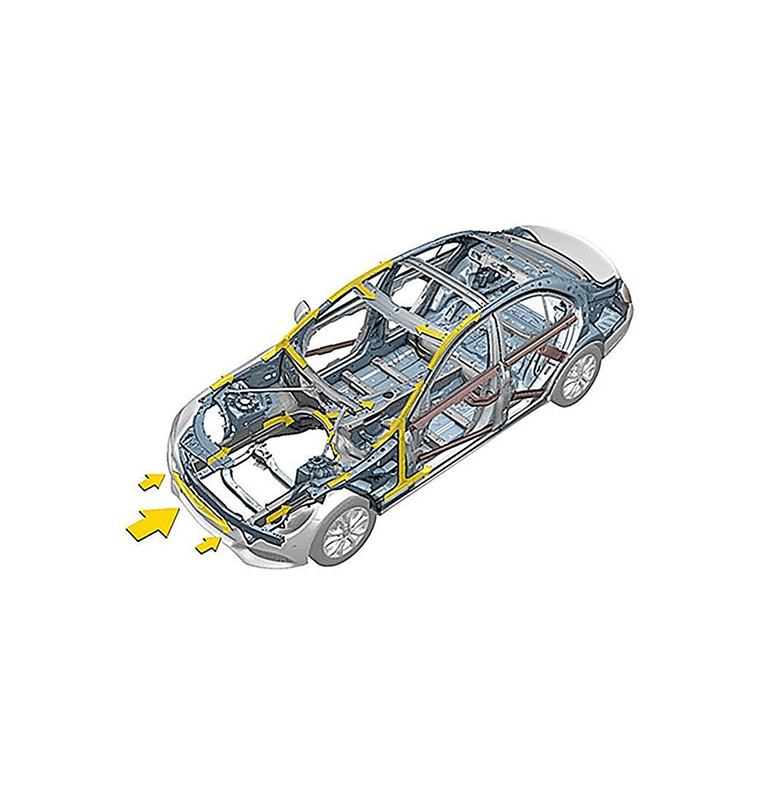

For crash management, the vehicle is designed to provide a load path that protects the occupants. Think of the force of a car hitting another vehicle in the side. The load path is one where the incoming vehicle hits the rocker panel and the door first. These systems are designed to absorb and deflect energy from the passenger compartment. See the Tesla Model Y in Success Stories for a great video by Tesla on how crash management works. The AEC has already profiled rockers and roof supports; hence the focus here is on front and rear crashes.

Structural Benefit

The load path at the front and the rear: the point of impact is the fascia, which is an aesthetic plastic cover with little structural benefit. Doing the energy absorption work is the bumper beam, and behind it, the crash cans behind it. Follow the arrows on the image here to see how the crash energy is directed around the passenger compartment.

First, we will study the bumper beam, which will be referred as the bumper; next, the crash cans referred as crash boxes or crush cans. Finally, the energy transfers to the rails and is carried and diverted away from the safety cage.

Extrusions: The First Three Lines of Defense

In a frontal crash, the load path begins at the bumper structure. The aluminum extrusion crushes and absorbs energy. Next in line are the extruded crush (crash) cans. Energy then moves into the extruded rails and is then directed around the passenger compartment. The goal is to protect the passengers.

Today, we are studying the bumper beam, which will be referred as the bumper, and secondly, by the crash cans, also referred as crash boxes or crush cans.

Bumper & Crash Cans

The bumper and crash cans are the first line of defense to protect against impact in the front or rear. These components are positioned far from the center of gravity of the vehicle, which is advantageous in maintaining a low weight.

Extruded aluminum bumper systems are found on more than 50% of the vehicles, from the older and economical Chevy Cruz, to the newly designed 2021 Ford Mach-E electric car. The versatility and value are further recognized by the usage across powertrains, internal combustion engine (ICE), and electric (EV), and across body-in-white materials, steel, and aluminum-intensive body structures.

Feature: Ford Mach-E

The body is more than 90% steel, the vehicle is 36% heavier than the baseline Mustang, and there is 10% less space in the crumple zone—yet Ford decided that the best solution for the front bumper system was extruded aluminum.

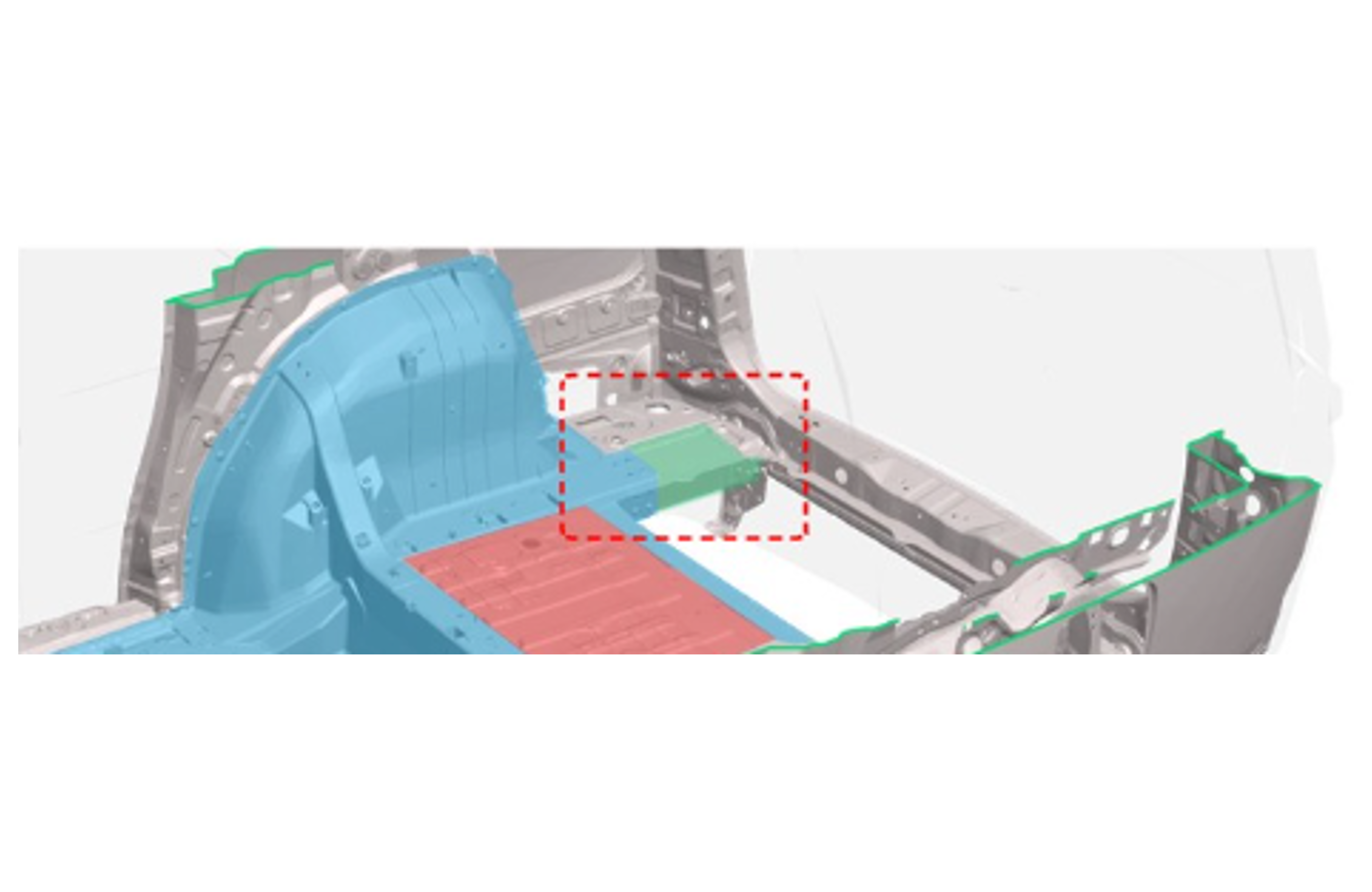

The Mustang Mach-E program paid particular attention to the small offset reinforced barrier (SORB) test. Ford set their sights on a 5-star rating. To achieve it, the bumper beam was extended outward from the crash cans in both directions. This image highlights the bumper beam extended portion, as well as the reinforcement in the crash can.

Multi-Hollow Bumper Beams

Crash Cans

Behind the bumper beam are the crash cans. These cans look like simple shapes, and are often welded to the beams, yet they are well-engineered products. Proper alloy design typically involves yield strength along with a measure of cracking tendency, according to an excellent technical paper from the Eleventh International Aluminum Extrusion Technology Seminar-ET '16, "Extrusions for Automotive Crash Applications" by N. Parsons, J-F. Beland, and J. Fourmann of Rio Tinto Aluminum. The properly designed can crushes like an accordion, without cracking. Each fold happens in a specific location as initiated by a physical modification to the corners - the Jeep Compass has holes on the corners, whereas the can below has impressions on the flat surfaces.

It is imperative to use computer-aided engineering (CAE) tools to simulate reality in the materials and in the systems to produce a reliable car or truck in a timely and profitable fashion. Millions of hours are spent doing CAE across the car, and it is equally important that the CAE engineers have good material data for their models.

An increasing number of vehicles are including new lower structure which is is referred as a “2nd crash path.”

Simulations for Optimal Design

The extrusion community has been generating good data through simulation on real vehicles and with consistent manufacturing processes. The images here show how a well simulated crash can performs to the real crash can. Source: SAPA presentation, Dr. David Lukasak, 2017.

Rails

Extruded aluminum rails significantly enhance light-duty vehicles through superior energy absorption and deformation resistance compared to steel components. These rails, primarily composed of aluminum alloys like 6061, are beneficial due to their high strength-to-weight ratio and excellent corrosion resistance. Optimized extruded aluminum rails absorb higher strain energy while maintaining structural integrity during rear impacts and jounce load cases. This makes them a preferable choice for improving vehicle safety and reducing overall weight, ultimately enhancing performance and fuel efficiency in light-duty vehicles.

Load Cases:

Load cases for these extrusions include static loads such as the weight of the vehicle and dynamic loads from acceleration, braking, and cornering. Impact loads from collisions are also a significant consideration. The ability to absorb energy without exceeding maximum load limits is crucial (Source: Extrusions for Automotive Crash Applications technical paper). From the firewall extending forward, the rail carries all the weight of the subframe, engine or electric motor and the shock towers. Stiffness is critical to minimize NVH and good ride quality which is the reason for the tall box sections, as used on the Tesla Model S. This video provides an informative conversation on the extruded rails.

Advantage of aluminum versus steel:

Aluminum rails offer several advantages over steel, including lighter weight, which contributes to improved fuel efficiency and vehicle handling. Aluminum also provides better corrosion resistance and greater design flexibility due to its ability to be extruded into complex shapes. To compensate for the lower modulus of aluminum, the walls may need to be thicker than that of steel. (Source: “Designing with Aluminum Extrusion, Part 1,” C. Werner, Light Metal Age, April 2013).

Aluminum extrusions can be formed into various profiles, such as hollow sections, multi-void structures, and intricate shapes that are difficult to achieve with other materials. The wall thickness of these extrusions is typically optimized to balance strength and weight, with thinner walls achievable through higher strength alloys (Source: Extrusions for Automotive Crash Applications technical paper).

The use of extruded aluminum rails in light-duty vehicles is a sophisticated approach to enhance performance, safety, and efficiency.

Advantage of extrusions versus giga castings

In a comparison of two EV’s, one uses an aluminum casting that incorporates the rails within it. The second is also an aluminum giga casting yet the rails are bolt-on extrusions rather than part of the casting. The Tesla Model Y has the single-piece casting, and if it is damaged in a rear-end accident, either the casting is replaced, or if the service shop is capable, they will attempt to weld it. The better solution is on the ZEEKR 009, where the rails are bolt-on extrusions. If this vehicle is in a rear impact event, the rails are simply removed, replaced at minimal time and cost.

Ready to get started? Find an extruder