Environmental Stewardship

An important lesson imparted to students is to be a good steward of our world. The school they are in should reflect that principle. High performance aluminum extrusions play key roles in energy efficient and resilient building design, renewable and net zero energy buildings, and the selection of responsible materials for environmental and health safety.

Energy Efficiency

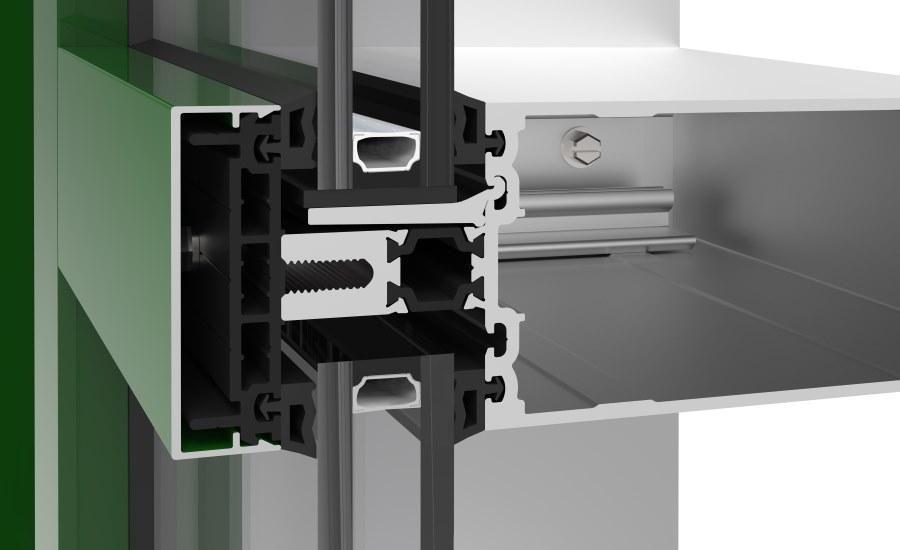

The energy efficiency of aluminum framed windows, doors, and skylights has advanced dramatically over time with the newest advanced thermal barrier technology and high performance low-e glazing providing energy efficiency equal to or better than alternative fenestration. To limit heat loss, framing now incorporates new advanced thermal barrier technologies such as wide thermal strut systems, dual cavity pour-and-debridge, polyamide pressure plates, and even structural foam thermal barriers. Glazing systems have advanced with spectrally selective low-e glass, multiple low-e coatings, warm edge spacers, and inert gas fill.

Kawneer Company, Inc

Sunshades & Light Shelves

Aluminum-framed windows, sunshades, and light shelves provide optimized daylighting and glare control to reduce lighting and cooling energy use. Even with high efficiency LED lighting, lighting still accounts for a major portion of building energy loads. Daylight harvesting offers a key efficiency measure for reducing this energy load. In fact, LED lighting has made daylight responsive controls more effective, controllable, reliable, and cost effective. The superior structural performance of aluminum framing allows narrow sightlines and long spans to maximize daylight openings. Extruded aluminum light shelves can facilitate "throwing" light into areas deeper in the building, while extruded sunshades and louvers can help balance daylighting with reduced glare and sun loading.

Important considerations in schools

Passive and resilient building design are also important considerations in schools.

To reduce air conditioning costs, operable windows and sunshades provide natural ventilation and shading for passive cooling. Operable windows and sunshades are further elements of resilient design when schools are used as emergency shelters, where natural ventilation and shading are necessary to maintain living conditions in the event of power outages following storms.

Renewable Energy & Net Zero Schools

There are a growing number of net-zero energy schools across the country, where school districts are taking steps to integrate energy efficiency and renewable energy into their long term educational, environmental, and economic goals. Aluminum products support these goals in both energy efficiency and renewable energy.

An AEC analysis showed that PV mounting systems using aluminum extrusions are more economical than alternative materials for total cost of ownership including materials. This is especially true in rooftop applications where strength combined with light weight is important.

Building Integrated Photovoltaics (BIPV) can be incorporated in other places on the building beyond rooftop panels. This includes on top of sunshades, in spandrel portions of curtain wall, and in laminated glazing over walkways.

Responsible Materials

Energy efficiency is only one aspect of a green building. Equally important is the selection of responsible materials. Aluminum extrusions offer full recyclability, long lasting durability, and positive life cycle benefits to support the circular economy - unlike fossil-fuel based plastics.

Performance Metrics

In addition to offering superior durability to ensure long-lasting performance, aluminum extrusions are fully recyclable without loss of performance:

- 75% of all aluminum ever produced is still in use today (Aluminum Association)

- 95% of aluminum in buildings is recycled at the end of its life because of its high value and recyclability (Delft University, 2004)

- -92% The reduction in energy use when producing recycled aluminum versus producing primary metal

- 35 - 55% The scrap content of typical extrusions produced in North America. Note that actual scrap content may be significantly higher or lower depending on the supplier and application. Mill finish product typically has a higher scrap content and anodized architectural product a lower scrap content.

Leadership in Energy & Environmental Design

These statistics lead to very favorable life cycle characteristics that offer material selection credits under LEED and other green programs. The Aluminum Extruders Council has produced two industry-wide environmental product declarations (EPDs) quantifying the "cradle-to-gate" environmental impacts of aluminum extrusions. One is for thermally improved aluminum extrusions, while the other is for extrusions without thermal barriers. Both provide data for mill finish, anodized, and painted finishes. These EPDs and other life cycle assessment data are available here.

Toxicity Free

Aluminum extrusion products can also help designers to avoid "Red List materials." Groups such as the International Living Futures Institute (ILFI) and their Living Building Challenge have compiled lists of chemicals and compounds considered to be worst-in-class materials in terms of toxicity or health impacts when used in products for the building industry. Avoiding these Red List products is intended to ensure that building occupant health is protected, including for students and teachers. Aluminum extrusions as well as polyurethane and polyamide thermal barrier materials are not considered toxic and do not appear on the Red List. Read more about this in the white paper "Aluminum Extrusions: Building Occupant Health and Safety."

Aluminum extrusions in building materials are naturally free of Volatile Organic Compounds (VOCs), whether in mill finish, anodized, or painted.

Low-VOC liquid paints are managed during application in the manufacturing facility and are not associated with off-gassing from cured, final product.

Designers, school districts, students, parents, and staff can feel comfortable choosing aluminum as an environmentally responsible and safe material.

Additional Resources

- "Daylighting, Views, Health, and Wellness: The Role of Extruded Aluminum Building Components", AEC whitepaper

- "Material Substitution Dynamics in PV Mounting Structures", IBIS Associates , AEC whitepaper

- "2019 Zero Energy Schools Watchlist", New Buildings Institute

- "Aluminum Extrusions: Building Occupant Health and Safety", AEC whitepaper

- Aluminum Extrusion Environmental Product Declarations and Life Cycle Assessment, AEC

Ready to get started? Find an extruder