Numerous vehicles take advantage of the attributes of aluminum extrusions to produce lightweight and long-lasting, safety-enhancing, aluminum rockers, which are also referred to as sills.

Select the vehicle below to learn more.

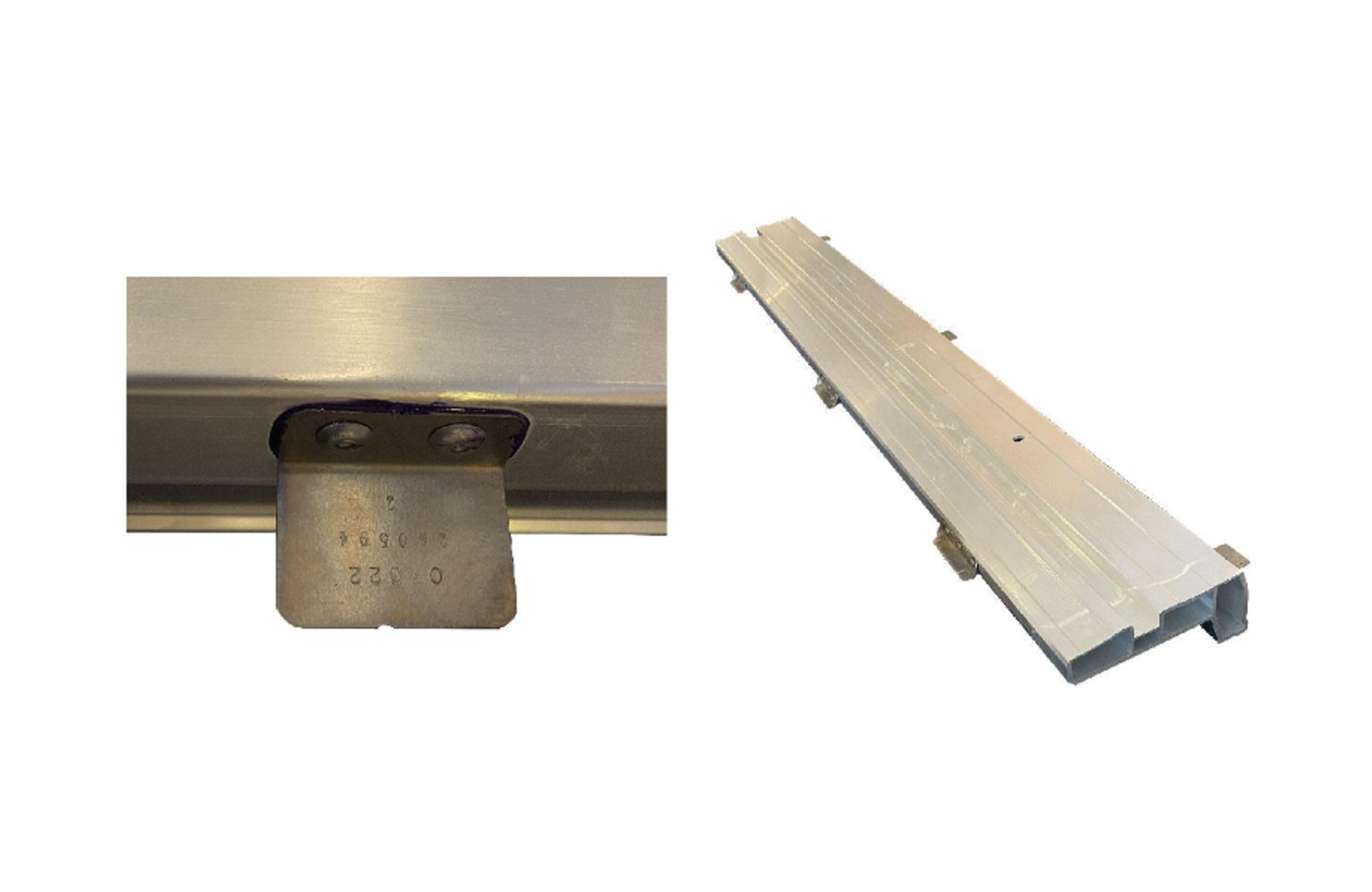

2022 GMC Hummer EV

Steel bracket is attached with rivets. Between steel and aluminum is a polymer adhesive to prevent galvanic corrosion.

2015 Ford F-150

Metrics to Success in Body and Chassis Extrusions:

- Tight Tolerances

- Controlled aluminum alloy grain structure

- Straightness (Profile Tolerances)

- Stringent mechanical property requirements

- Versatile to various assembly techniques

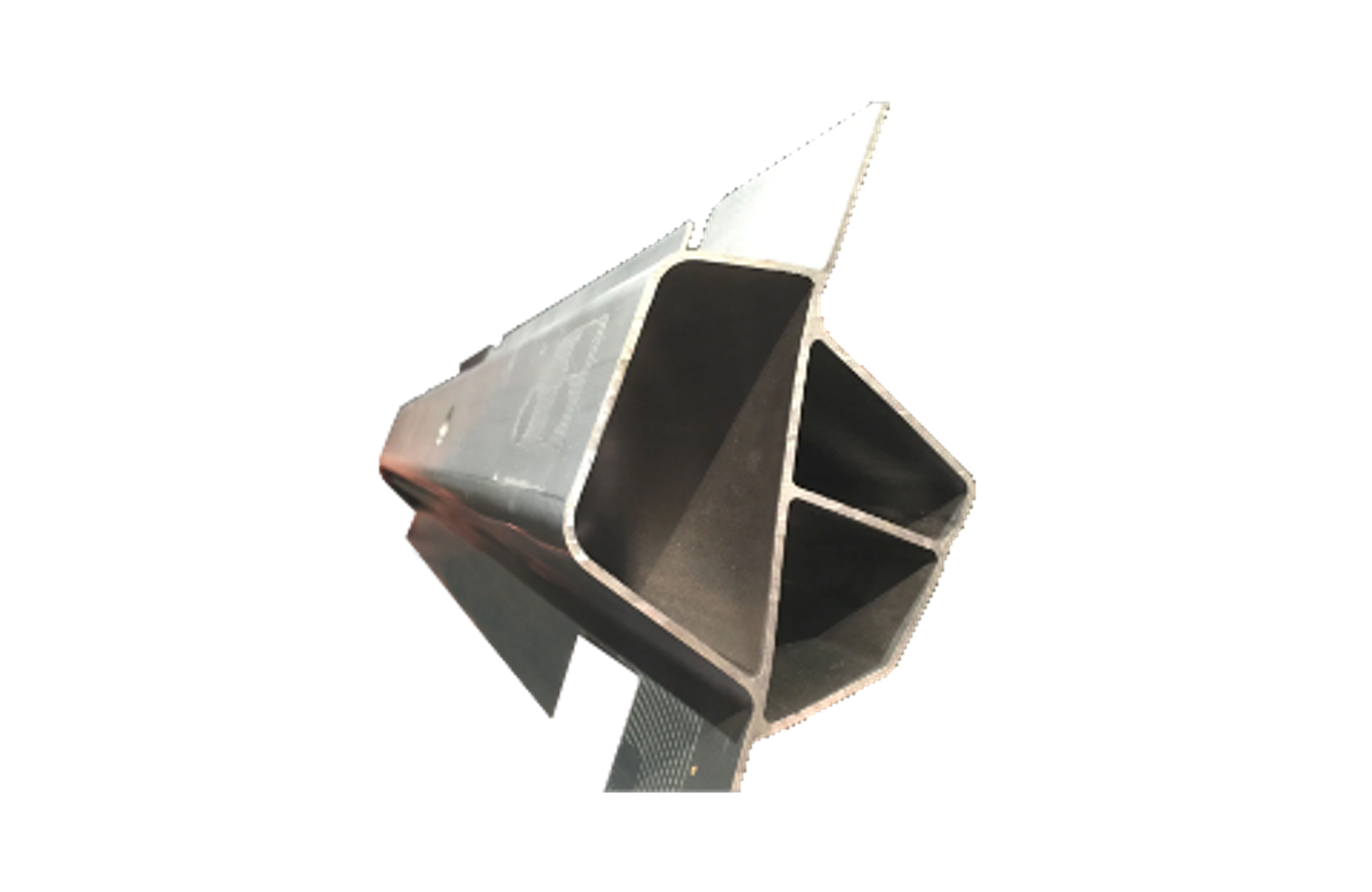

BMW i3 EV

One-piece rocker panel reinforcement

- Multi-hollow

- Structural extrusion

- Efficient product performance

2024 Tesla Model 3

Extrusion Content:

- Rails - front

- Rockers

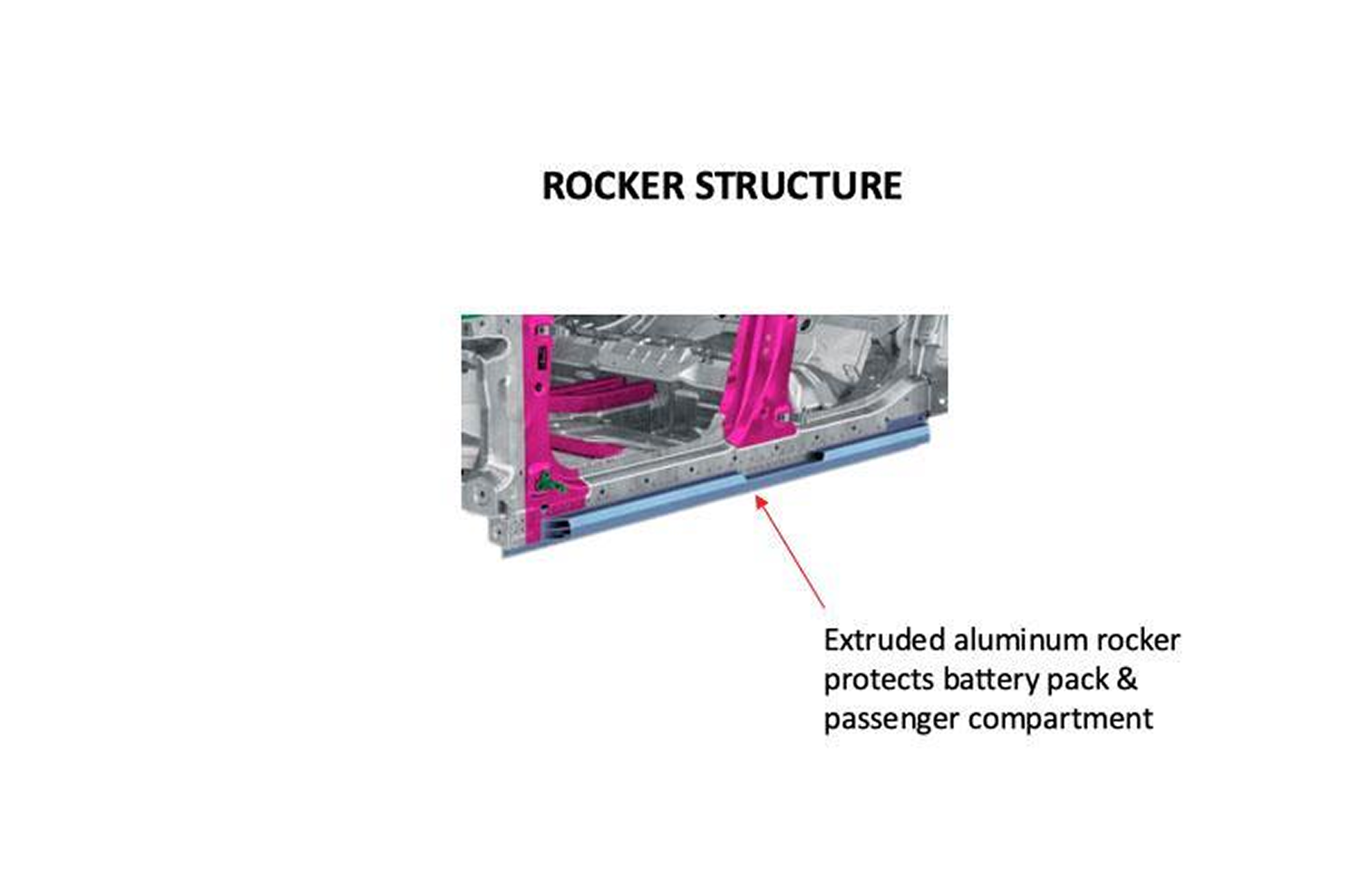

2022 Porsche Taycan EV

Rocker Structure

- Extruded aluminum rocker protects battery pack and passenger compartment

Hyundai IONIQ 5

Extrusion Benefits

- Passenger and battery protection

- Tight tolerances

- Multi-hollow extrusion

- Long length, straight

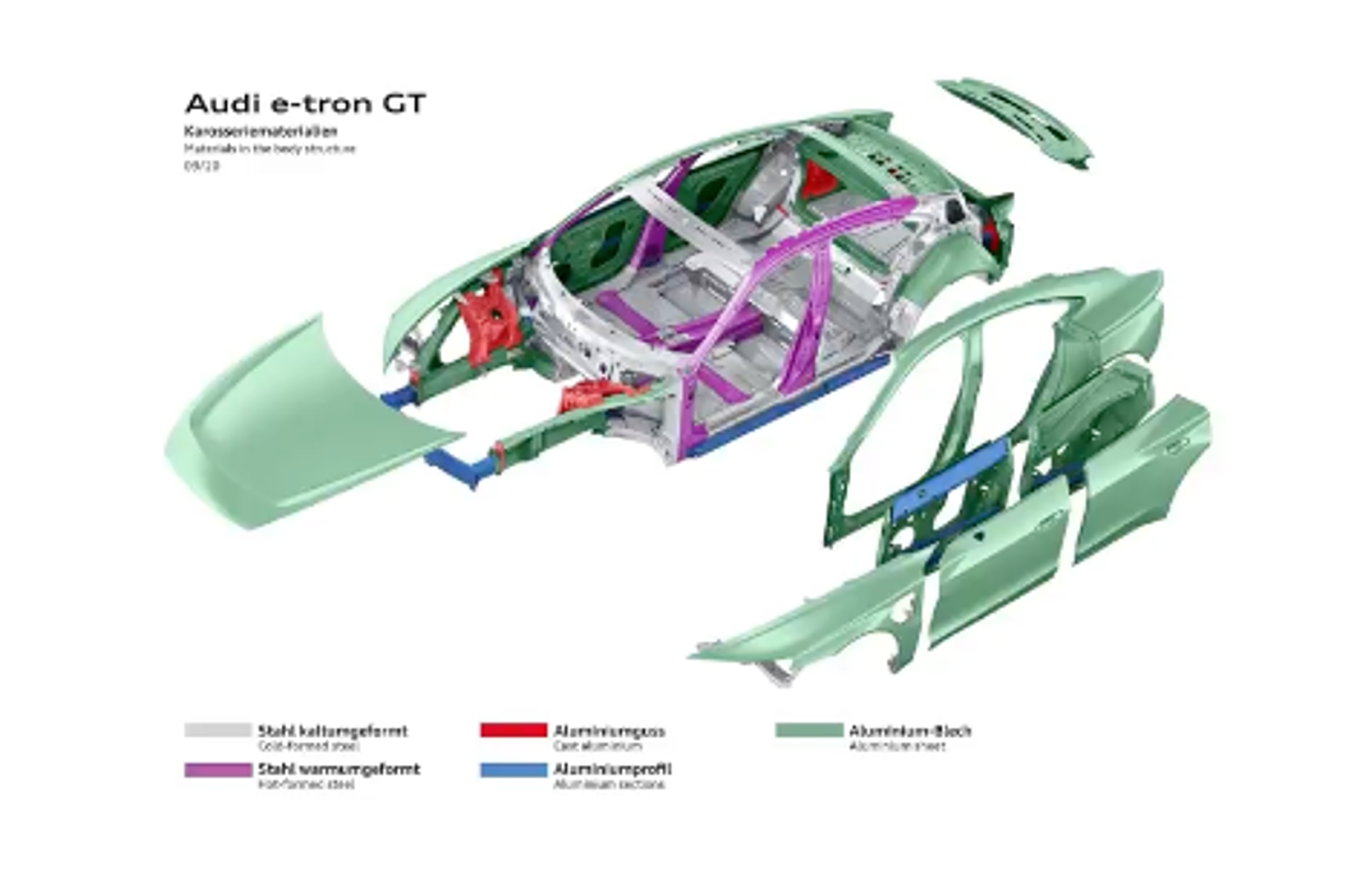

Audi E-TRON GT

Extrusion Content:

- Rails

- Rockers

- Bumper Beam

- Door intrusion beam

BMW i7 xDrive 60

Extrusion benefits:

- Passenger and battery protection

- Tight tolerances

- Multi-hollow extrusion

- Long length, straight

2023 Tesla Model S Plaid

Extrusion Content

- Rails

- Rockers

- Cross-members including toe board

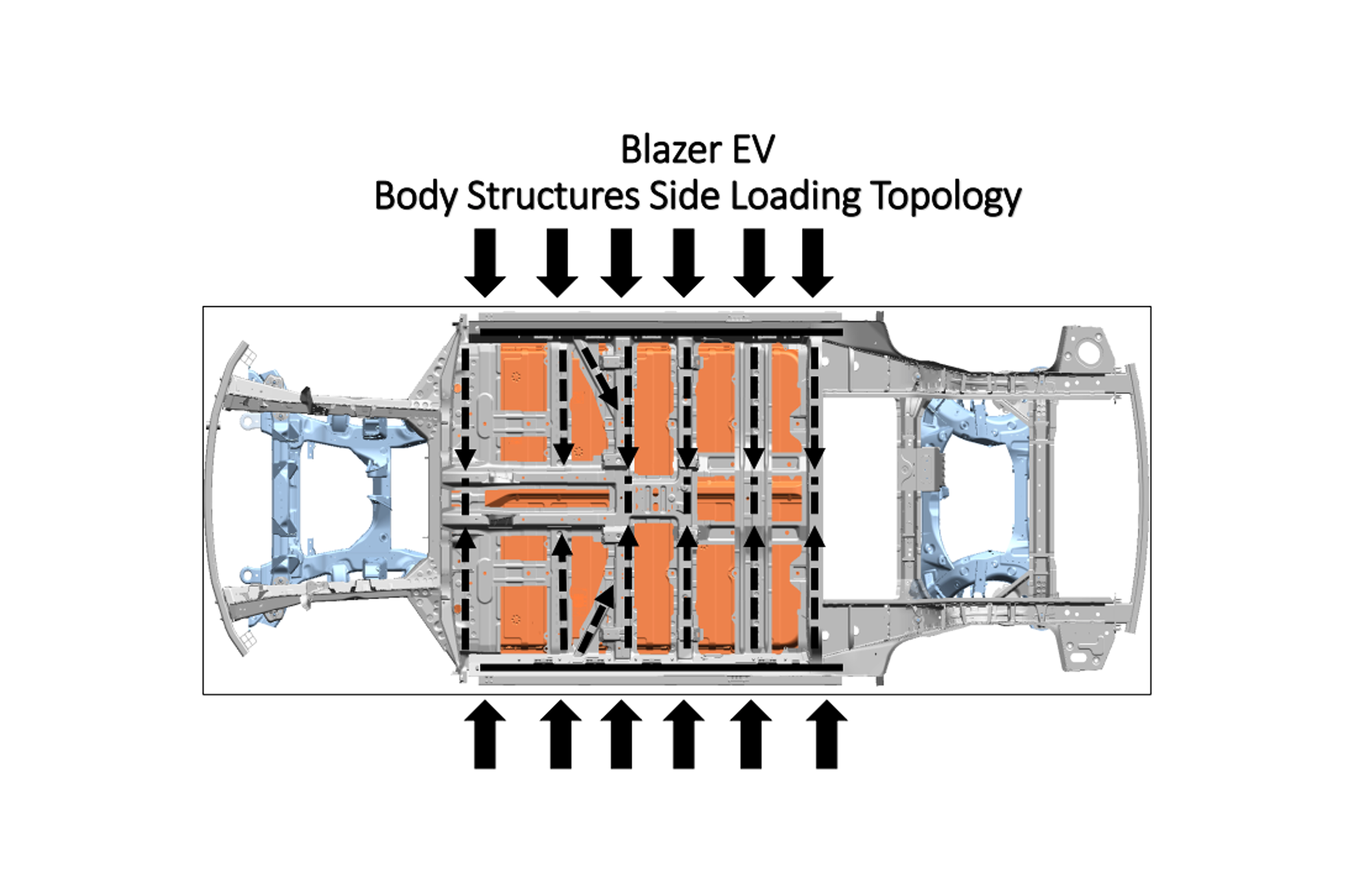

2024 Chevrolet Blazer EV

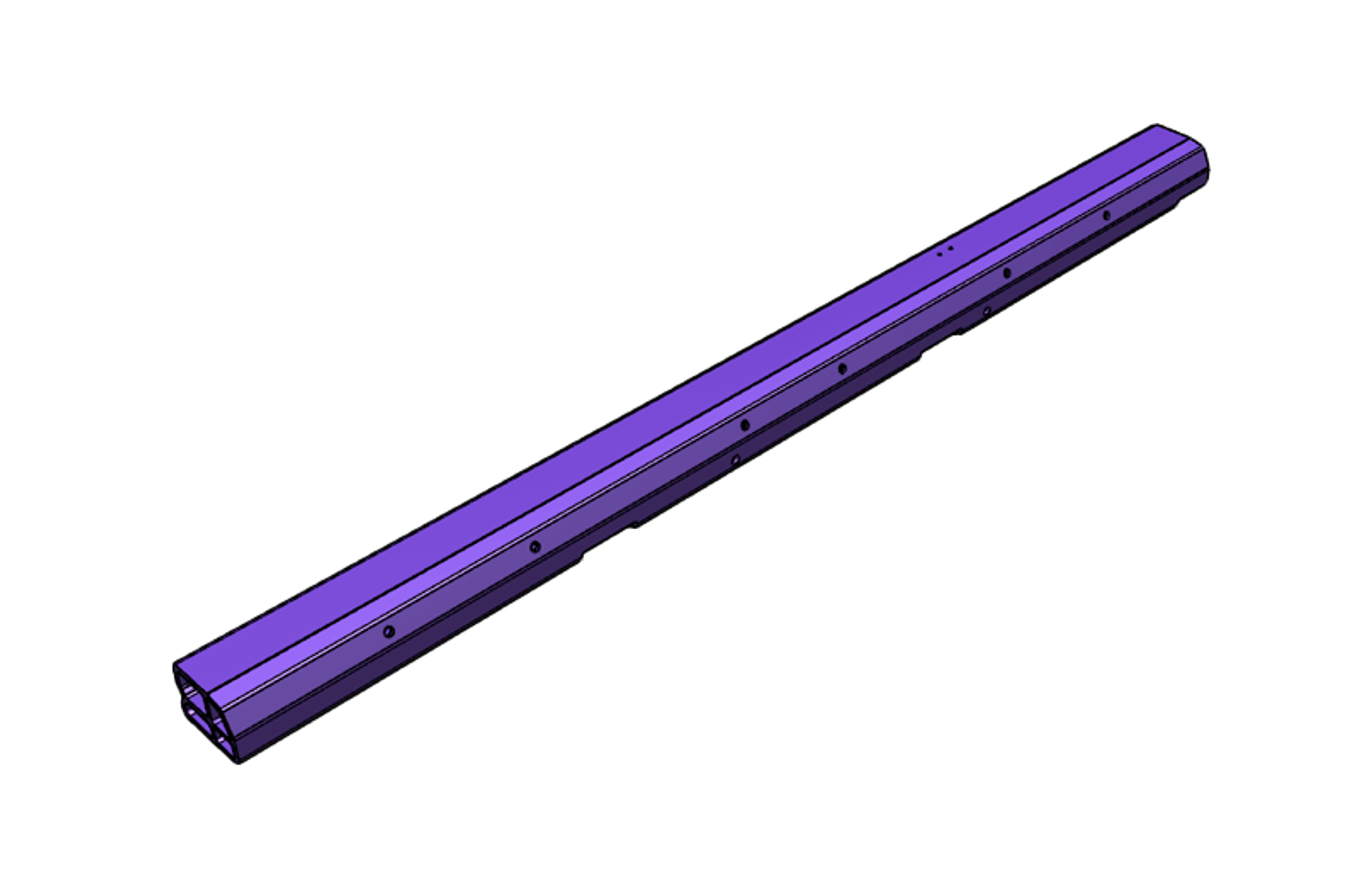

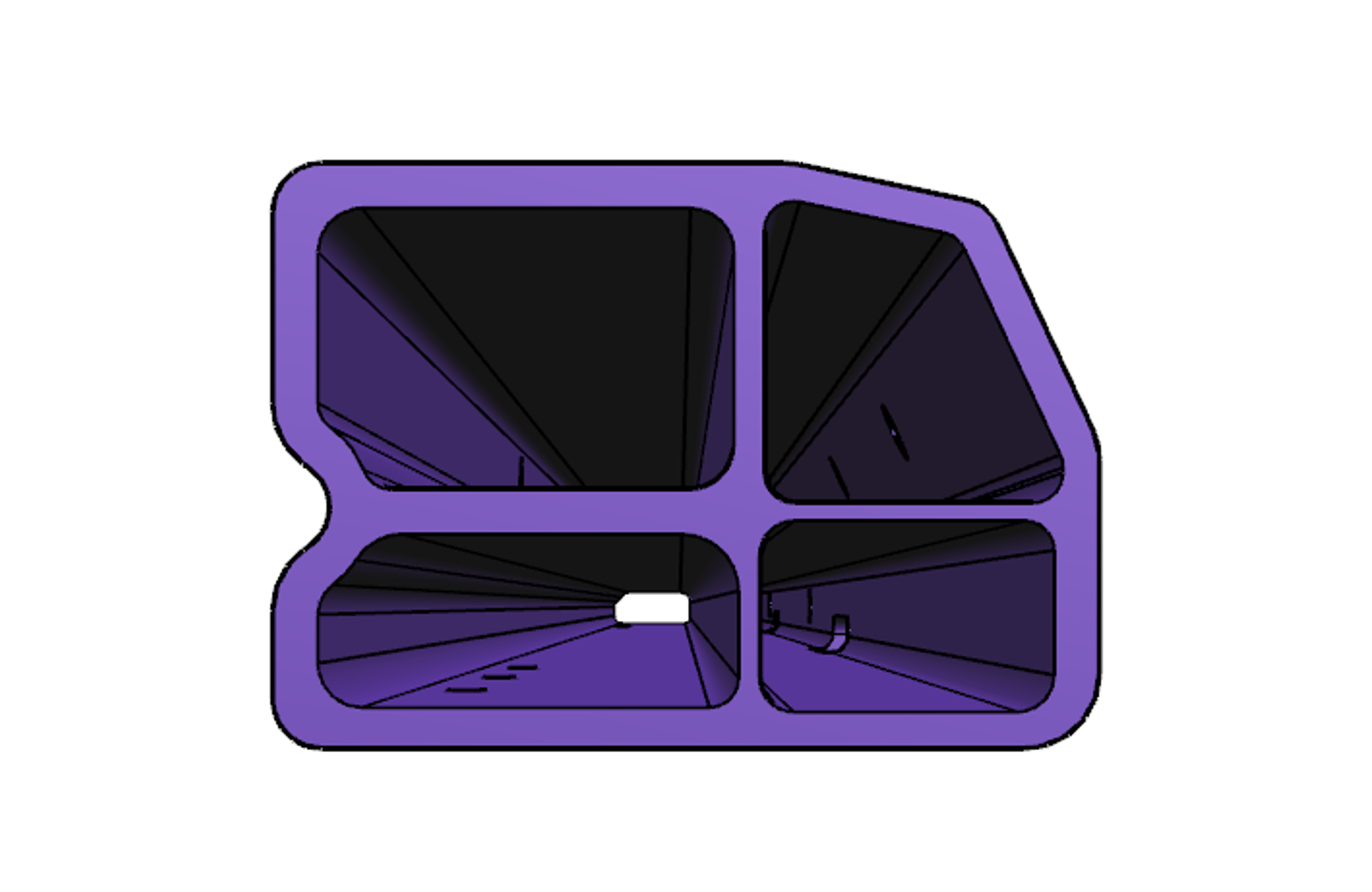

Extrusion: 6082-T6 Rocker

This rocker is common to other vehicles within GM’s BEV Architecture. In addition to the Blazer EV, the other models include:

- Buick Electra E5

- Buick Electra E4

- Cadillac Optiq

- Chevy Equinox EV

- Cadillac LYRIQ

- Honda Prologue

- Acura ZDX EV

- Future Variants

2023 Lexus RZ

Extrusions: 6-Hollow Rocker/Battery Protection

2023 Tesla Model Y

Extrusion Content:

- Rear rails

- Rockers

- Cross-member

2025 Volvo EX-30

Extrusion Content:

- Bumpers

- Rails

- Rockers

Ready to get started? Find an extruder