There are a number of vehicles that utilize the attributes of aluminum extrusions to produce lightweight and long-lasting aluminum subframes and engine cradles.

Select the vehicle below to learn more.

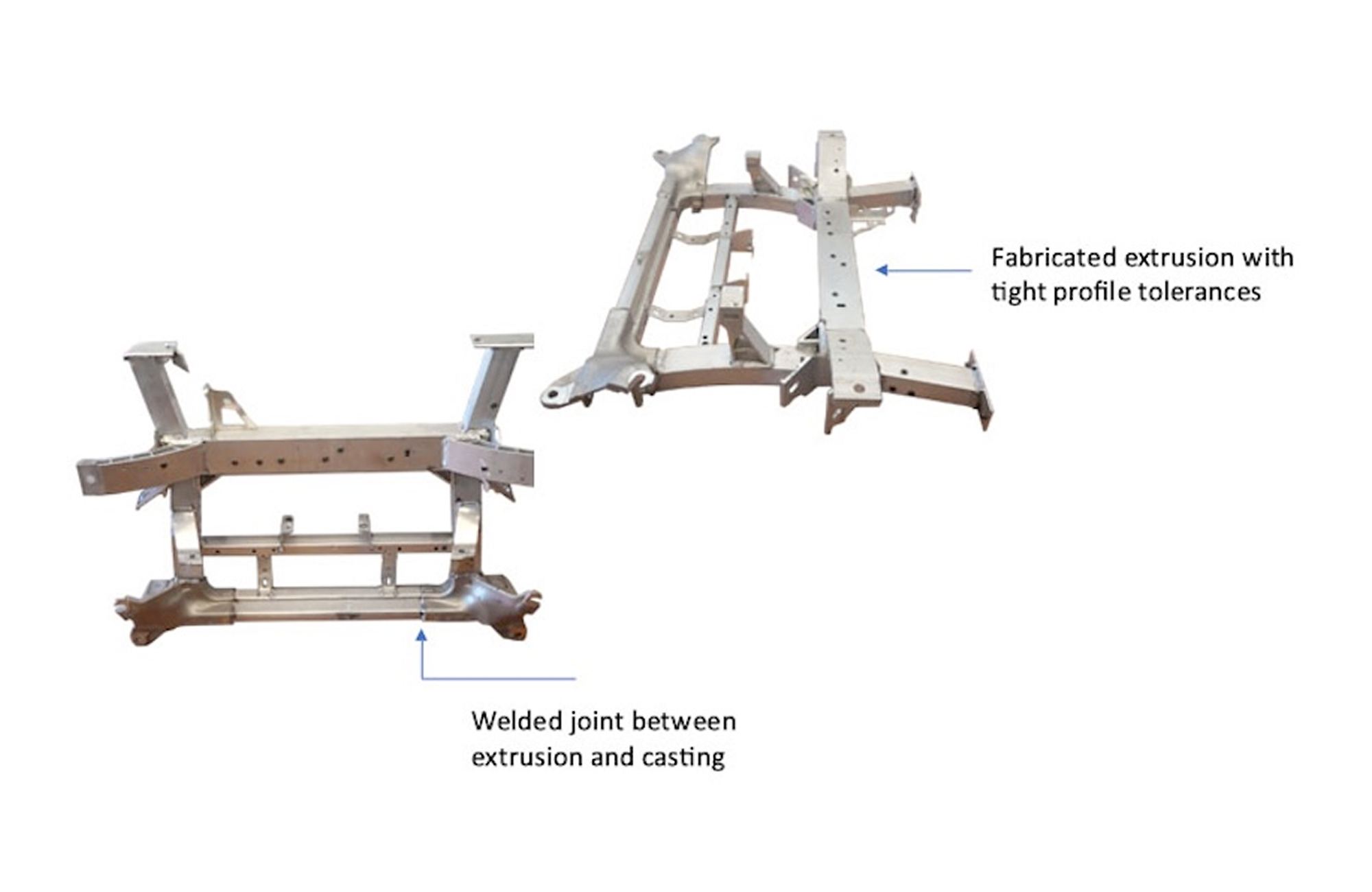

2015 Tesla Model S

Front-based Extrusions

- Construction: Extrusions & Castings, Welded

- Fabricated extrusion with tight profile tolerances

- Welded joint between extrusion & casting

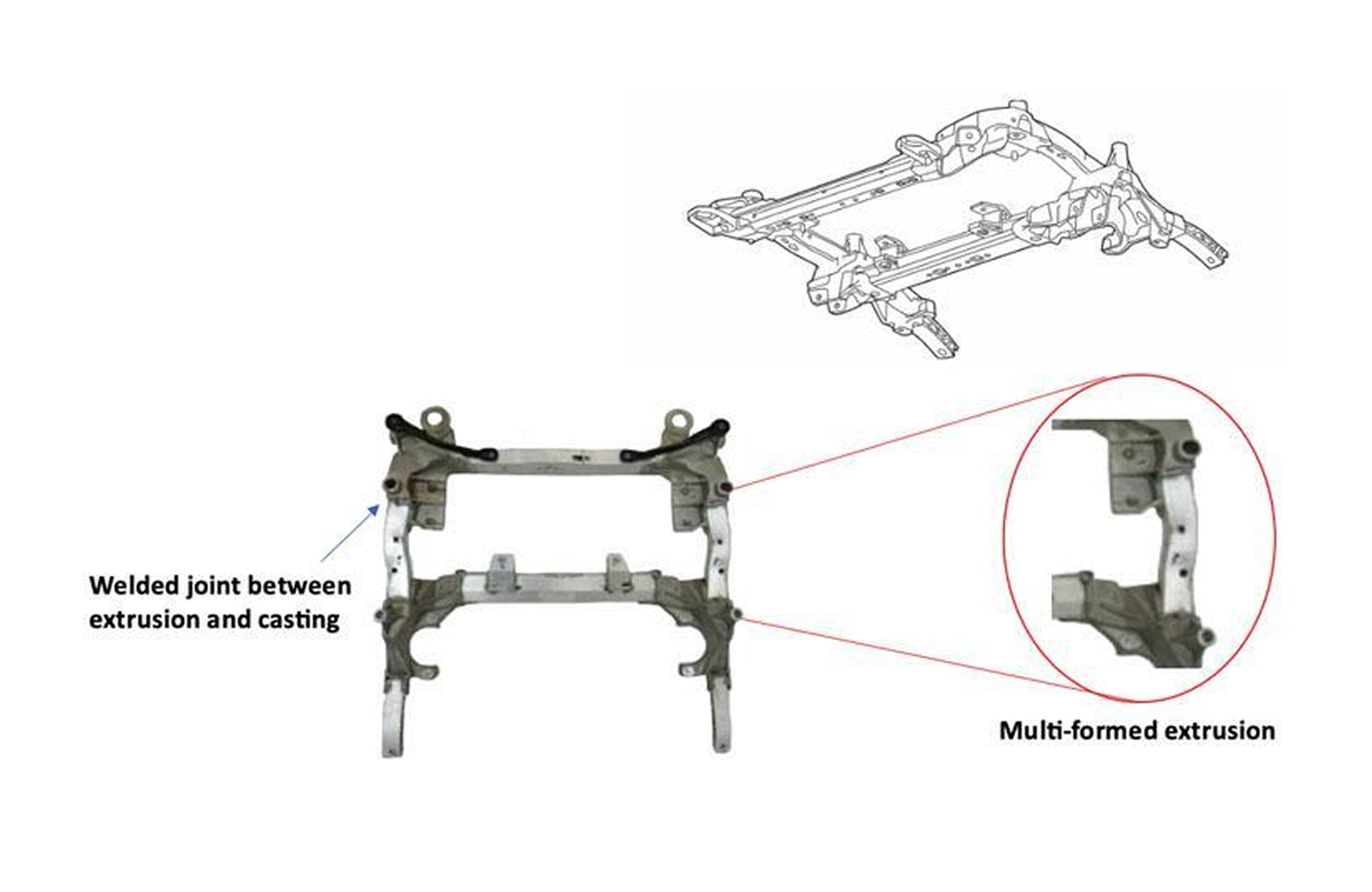

2018 Chevy Camaro

Front-based Extrusions

- Construction: Extrusions & Castings, Welded

- Welded joint between extrusion & casting, multi-formed extrusion

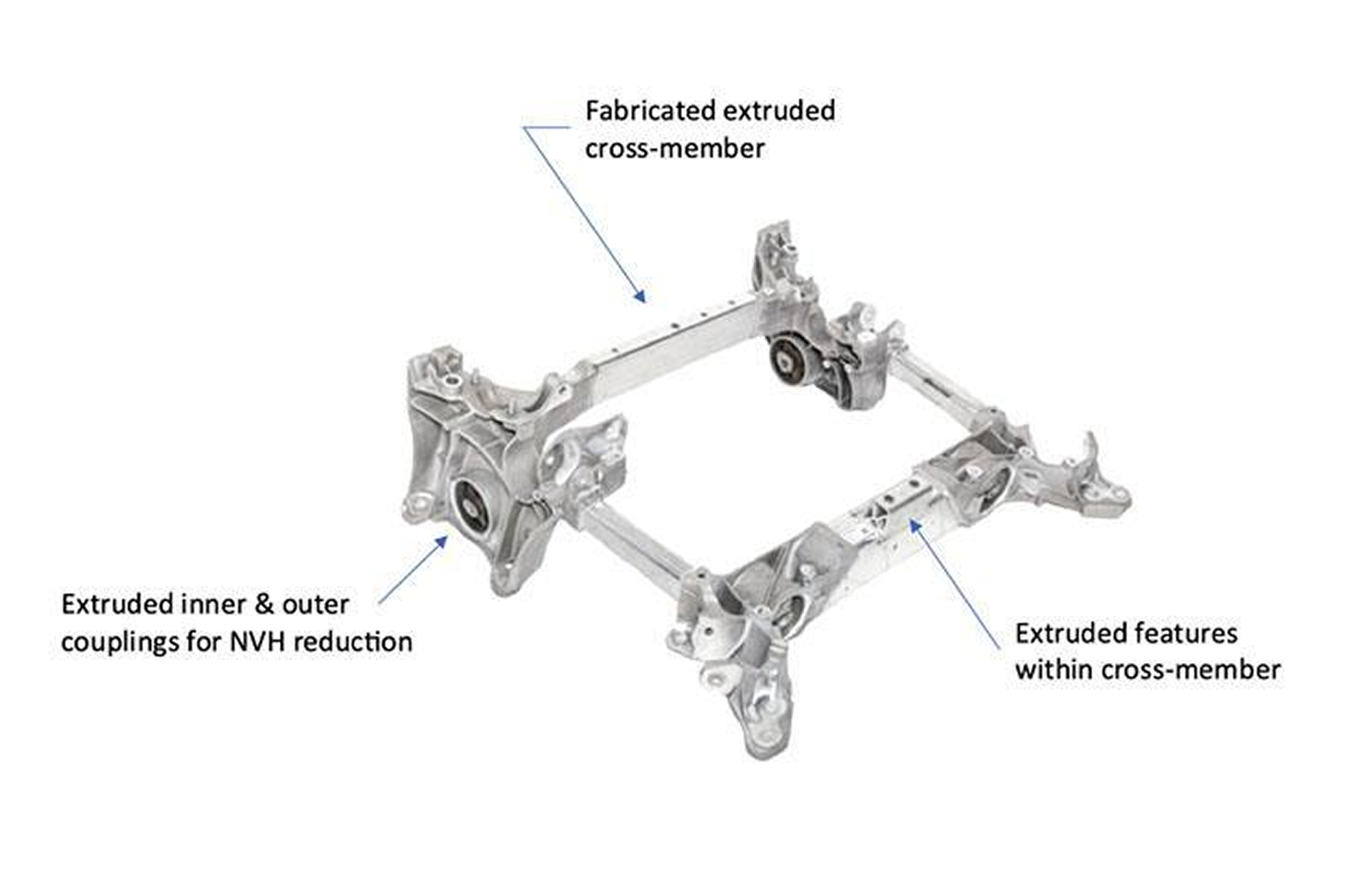

Audi E-TRON SUV

Front-based Extrusions

- Construction: Extrusions & Castings, Welded

- Fabricated extruded cross-member

- Extruded features within cross-member

- Extruded inner & outer couplings for NVH reduction

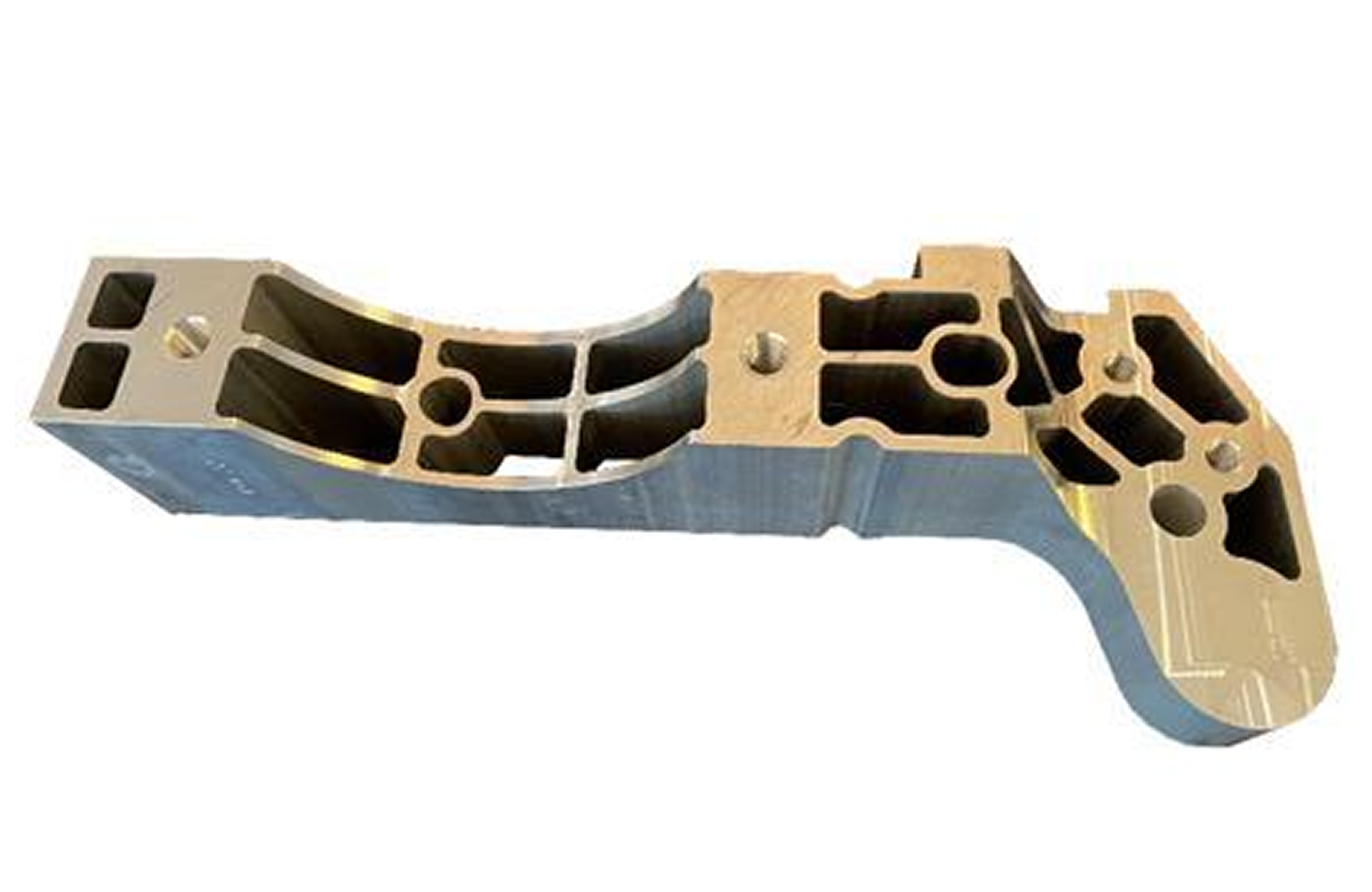

2022 Rivian R1T

Front Subframe Extrusions

- Construction: aluminum extrusions, welded

- Cradle mount extrusion

- 18 hollows

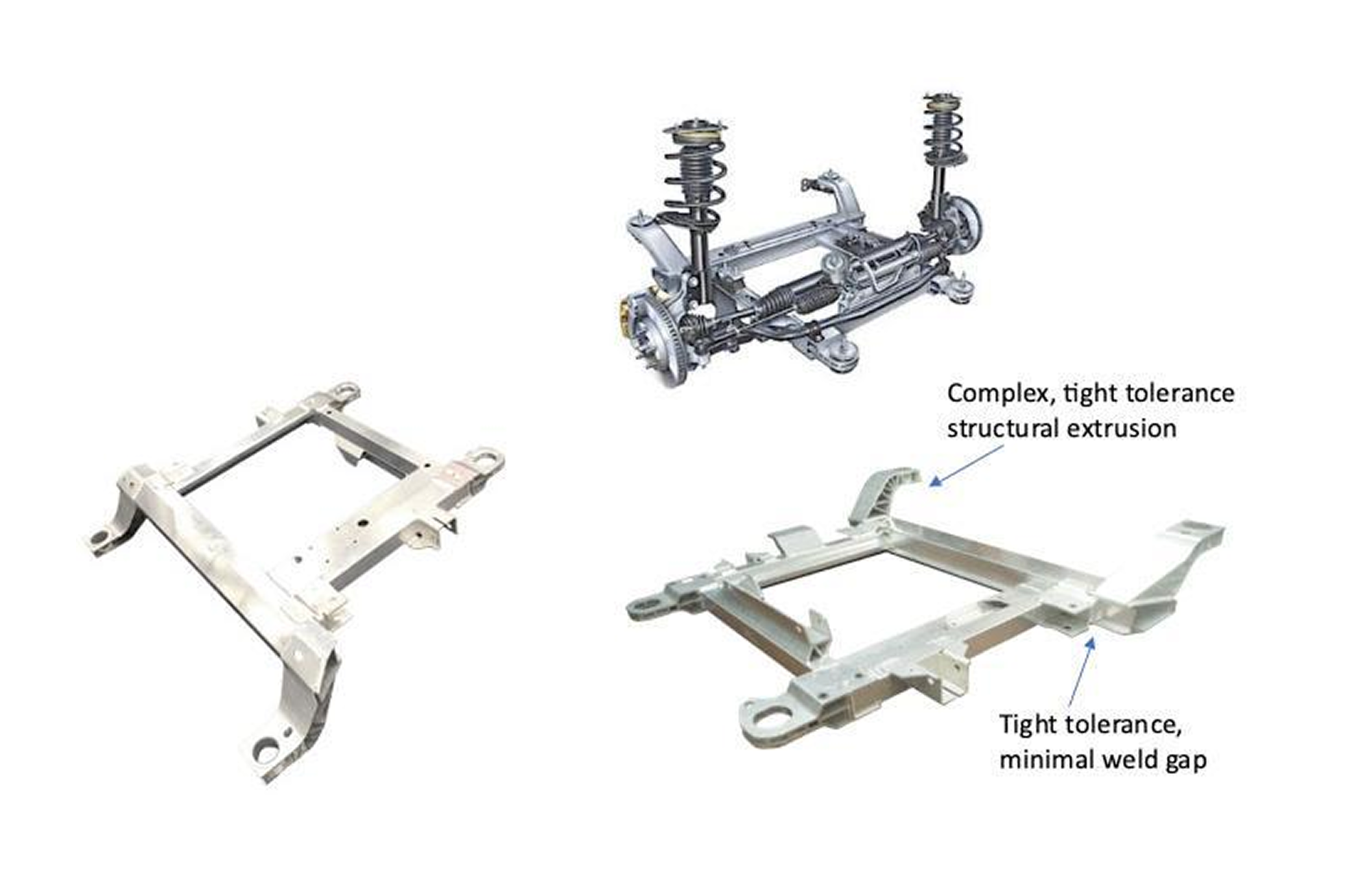

2013 Chevy Impala

Front-based Extrusions

- Construction: all extrusions, multi-alloy, tempers, welded

- Complex, tight tolerance structural extrusion

- Tight tolerance, minimal weld gap

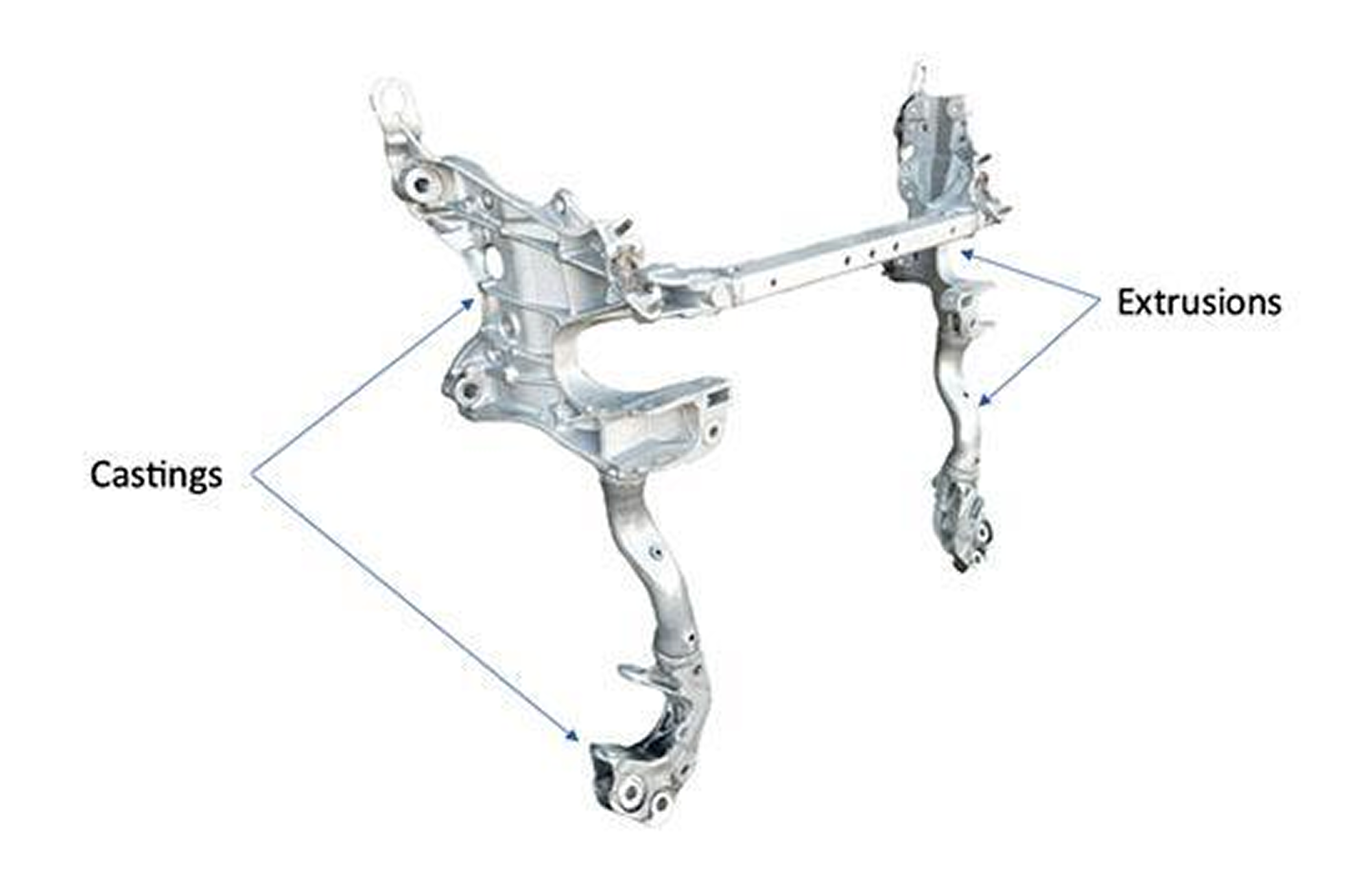

Audi A5/S5

Front-based Extrusions

- Construction: Extrusions & Castings, Welded

- Complex assembly utilizing engineered castings and extrusions

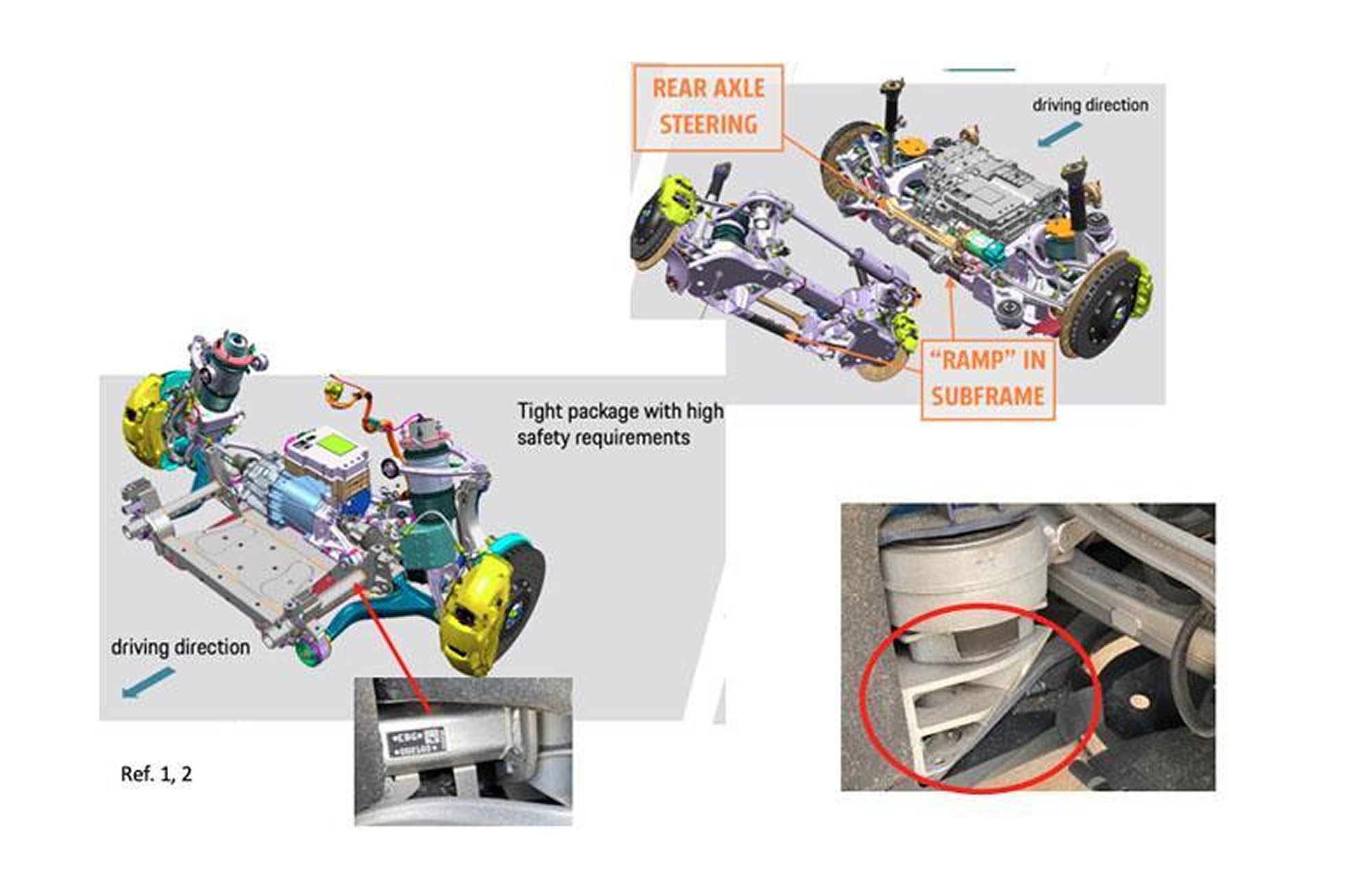

Porsche Taycan EV

Extruded Components

- Construction: Extrusions & Castings, Welded

- Tight package with high safety requirements

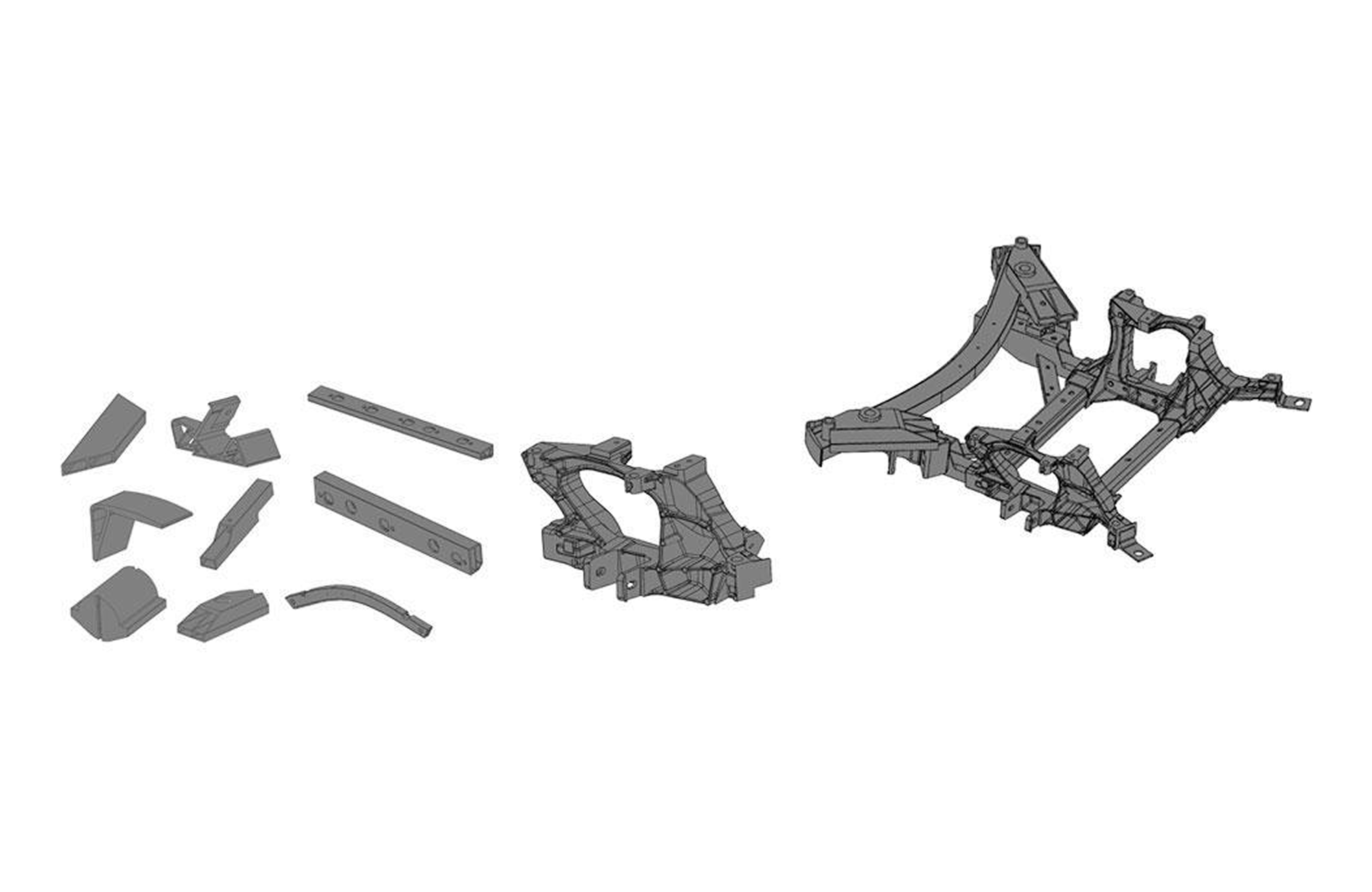

2022 Jeep Grand Cherokee

Front-based extrusions

- Construction: engine cradle, aluminum extrusions & castings

- Hybrid construction: 9 extrusion profiles with 2 aluminum castings

2024 Mercedes-AMG EQE SUV

- Hybrid aluminum subframe, extrusions & castings, welded

2025 Polestar 3

Front Subframe, Extrusions, Welded

Battery Protection & Support

- Between the subframe and the battery is this extrusion that provides debris protection & structural support.

Ready to get started? Find an extruder