2025 Design Competition

Winning Entries Announced

August 5, 2025; Wauconda, Illinois – The Aluminum Extruders Council (AEC) and the Extrusion Technology Foundation (ET Foundation) have announced the winning entries in the 2025 International Aluminum Extrusion Student Design Competition. University, college, design, and high school students from around the world submitted 70 entries for the opportunity to receive a cash scholarship award.

AEC Extruder Members Almag Aluminum, Brampton, ON, Canada; MI Metals, Inc., Oldsmar, FL; and Pennex Aluminum Company LLC, Wellsville, PA, sponsored the cash scholarship prizes, which totaled $15,500. Judges for the competition included Mark Butterfield, AEC Chairman, ET Seminar Committee Vice Chairman and President of MX Holdings/Pennex Aluminum Company LLC, Wellsville, Pennsylvania; ET Immediate Past Chairman, Craig Werner, President and CEO of Werner Extrusion Solutions LLC, Lake Forest, Illinois; and Shane Tredup, At-large member of the AEC Board of Directors and Sustainability Team Leader and President of Custom Aluminum Products Inc., South Elgin, Illinois.

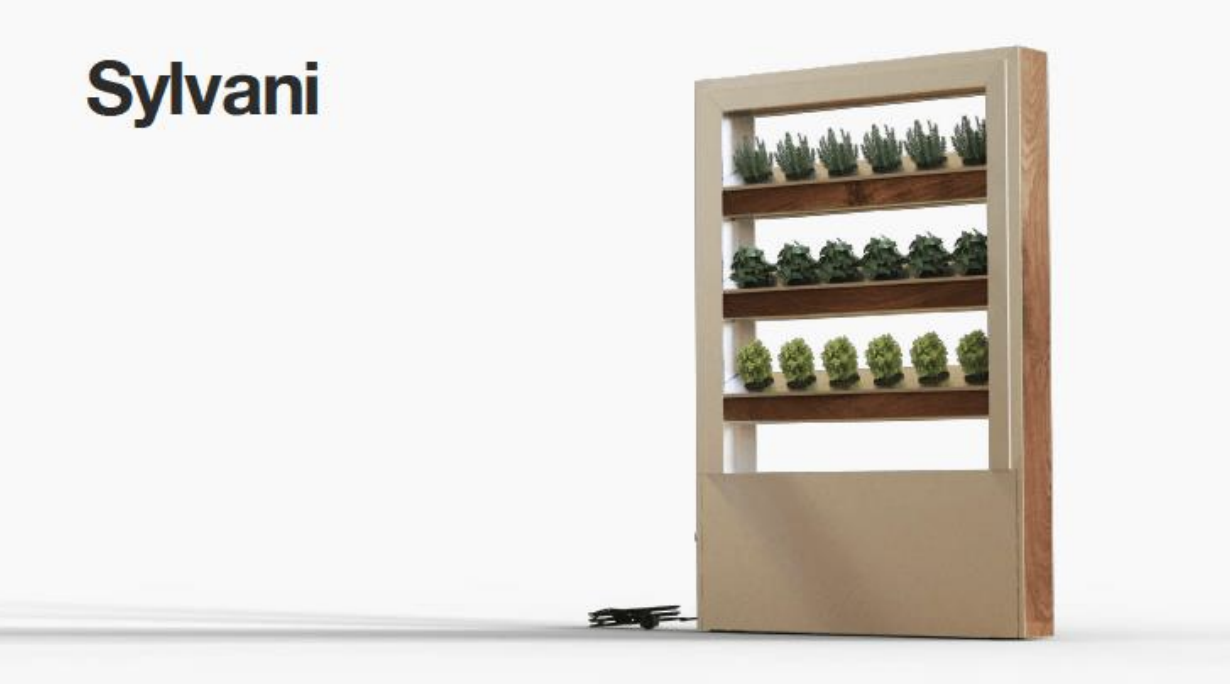

Ava Cannedy, a sophomore studying Industrial Design at Purdue University in West Lafayette, Indiana, USA, received the First-Place award of $5,000 for her “Sylvani” self-sustaining kitchen garden, made from extruded aluminum components. The hydroponic garden structure automates plant care and brings freshly grown herbs and produce within easy reach. Her winning design provides a space-saving, efficient solution to growing vegetables and herbs at home in limited space, promoting healthier eating and sustainability. Hydroponics grows plants without soil using nutrient-rich water to deliver essential minerals directly to plant roots, allowing faster growth and efficient use of resources.

“Sylvani is an exceptional example of aluminum extrusion,” noted Cannedy. “It demonstrates the material’s versatility and strength, and ability to integrate multiple functions within a single structure. By utilizing the internal extrusion cavities for the water and electrical routing, the design maximizes space efficiency, reduces the need for external wiring or tubing, and enhances the stand’s overall aesthetics and durability. It’s a simple and beautiful way to grow plants in your home.” She specified aluminum for its strength, durability, corrosion-resistance, and machinability.

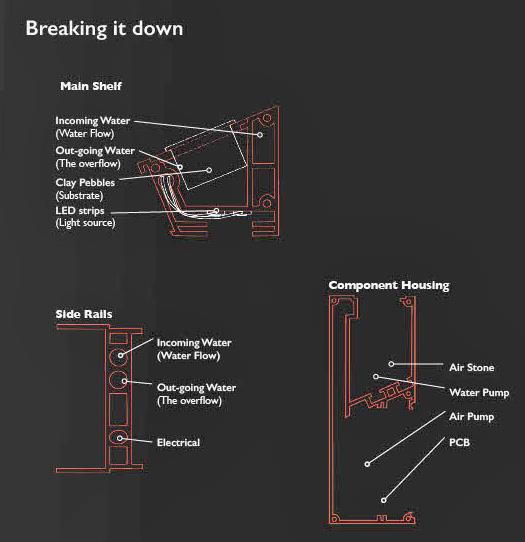

Cannedy’s sleek, automated gardening system design focuses on the efficient use of aluminum extrusions, using aluminum alloy 6016. Five main parts include the extruded component housing for the plant pots, decorative wood plank trim, main shelves, a top light and side rails – all interlocking to form a complete, functional unit that houses the water source and electrical for the LED light strips.

Her extruded aluminum main shelf design is drilled with holes where incoming water meets the main water chamber, allowing water flow. The extruded aluminum lid with punched holes holds the plant pots. A wooden plank and acrylic piece slide into integrated extrusion slots, adding aesthetics and diffusing LED light. Two LED strips adhere to the aluminum extrusion for heat dissipation, with a slot for wire management. Three screw bosses allow assembly into the side rails. Each side rail has a drilled hole for every shelf, aligning with the main water chamber in the shelves to the outgoing water flow tube, integrating into the aluminum extrusion as is the case for outgoing water and electricity.

The main component housing has one section for water storage and the other section for electronics. A removable top plate allows easy water pump installation. A screwed-in back plate provides access to the air pump and PCB, which controls the pumps and connects to the power cord. The system works seamlessly, beginning with the air pump oxygenating the water. The water pump then circulates water through the side rails into the main shelves. Overflow holes manage the water level before the water returns to the main chamber. Cannedy explained the indoor garden’s assembly.

“Sylvani is assembled by screwing the main shelves to the side rails with a rubber gasket in between to hold water. The top light also attaches to the side rails but without a gasket. The side rails sit on the component housing, connected by a screwed-in plate. A wooden plank, glued to the aluminum, hides the screws and adds aesthetic appeal,” she said, concluding, “Extruded aluminum is stable and durable, providing a sturdy frame that can support the weight of the water and plants. The aluminum is highly recyclable, making it a more environmentally friendly material choice.”

“Sylvani showcases the best use of extrusion in this competition,” commented competition judge Shane Tredup. “Extrusions are the backbone of this hydroponic garden. The design is both functional and artistic and utilizes aluminum extrusions to solve the practical issues of watering and lighting, eliminating traditional piping,” he stated.

Second Place, with a $4,000 scholarship prize, was awarded to Nil Tous Held of Montréal, Québec, Canada, an Industrial Design student at Dawson College in Montréal, for his ingenious design of the Alumina Tabletop Firepit. Aluminum extrusion was chosen for its excellent thermal conductivity, lightweight characteristics and corrosion resistance. Alloy 6063-T6 was chosen for its superior extrudability, enabling the integration of heat dissipation fins and flame adjustment controls directly into the body of the extrusion. The integrated design avoids fasteners or other assembly dependent components. The 6063-T6 alloy has a smooth finish ideal for anodizing, helping to ensure durability, corrosion resistance and aesthetic appeal.

“Extruded aluminum’s properties make it ideal for managing heat effectively, offering greater safety and usability than existing designs made exclusively from stainless steel, which tends to retain excessive heat that can become a hazard. This tabletop firepit creatively leverages aluminum’s unique capabilities to solve design challenges,” Held explained. “While tabletop firepit designs typically shrink design features of larger models, this design completely re-defines the product category, creating a new solution optimized specifically for compact and safe urban use,” he noted.

The firepit combines an extruded aluminum body with a stainless-steel core, strategically leveraging each material’s strengths: aluminum’s excellent heat conduction and light weight, and stainless steel’s high temperature resistance. The material combination enhances the unit’s performance, safety and usability. The main extrusion is the firepit body, which integrates structural support, heat dissipation fins, intuitive flame control, and an emergency extinguishing mechanisms into a single component. The integration simplifies manufacturing and assembly, reduces overall cost, and ensures precise, reliable functionality.

The competition judges liked Held’s design, calling it sleek and appealing. The judges appreciated the attractive design of the extrusion and wanted to use this unit on their own patios. “It’s a great-looking and functional solution for outdoor or indoor tabletop use. I want one!” noted judge Craig Werner. “The aluminum housing and small footprint makes it a practical and attractive solution that works well with any décor.”

Third Place with a $3,000 scholarship prize was awarded to Gene Lin, a sophomore studying Industrial Design at Purdue University in West Lafayette, Indiana, for his APEX hydrogen-powered rotary motor design for use in go-kart racing. The student sought to work in the hydrogen-powered space, as he observed that multiple categories have been introduced to experiment with race cars using different types of power units, moving from internal combustion engines to hybrid, electric or hydrogen-powered motors. Lin saw an opportunity to bring hydrogen power to an introductory racing series known as “karting”. He noted that when burned in the combustion chamber, hydrogen combines with oxygen and the resulting reaction only emits water.

Lin explained, “Unlike electric drivetrains, which require heavy batteries to create the power needed to handle racing, hydrogen provides a cleaner power source. Hydrogen burns quicker than gas, creating more torque low down. It counterbalances the rotary to create a balanced torque range and offers a hydrogen rotary engine that is light, powerful and clean. Lin designed the APEX to be built around a pre-existing racing kart chassis, where the hydrogen tank housing and rotary motor can easily be installed. The motor exhibits continuous combustion making the hydrogen-powered engine run smoother than piston motors. Limited and simple moving parts within the rotary facilitated components that can be extruded.”

The extrusion design has built-in apex seal channels, enabling the rotor to implement oil reservoirs and unite with the apex seals to form one part. Combined with an oil pump, Lin’s design enables constant oil being fed to keep the seals lubricated. The extrusions’ flexible characteristics include snap-fit housing joints for easy unlatching, so removing and installing the hydrogen tank is hassle free. Aluminum alloy 7075 was selected for its heat treatability and overall strength for the rotary motor. Alloy 6063 was chosen for the hydrogen tank housing for its heat conductivity and cost-effective strength, according to Lin.

Lin noted, “This design revolutionizes the go-kart motor by utilizing an unconventional motor that can also be built using aluminum extrusion. It still maintains what makes racing great, while reducing emissions with hydrogen power. Aluminum resists absorbing hydrogen and becoming brittle. Extruded aluminum aligns the grains to create a more uniform shape, making it up to two times stronger than cast aluminum,” Lin stated. “Karting motors require cooling fins and complex fluid reservoirs, matching well with extruded aluminum’s suitability for designing complex shapes.”

In the eyes of the judges, this winning design “is a diverse and creative use of aluminum extrusion, with functional advanced technology” explained judge Craig Werner, President and CEO of Werner Extruded Solutions and Past Chairman of the AEC Business Excellence Steering Committee. “The 6063 and 7075 alloys really lend themselves to aluminum extrusion’s thermal benefits. The design is extrudable as-is, working well in low volume for light-duty use with a hydrogen canister.”

The Sustainable Design Challenge award, earning a $3,500 scholarship prize was awarded to Elena Thomas of St. Louis, Missouri, studying Industrial Design at Purdue University, for her design of Veroto, an accessible and space-conserving vertical garden that provides easy access to any planter trough at any height. The goal of Veroto is to provide gardening or farming methods that are not limited by mobility impairments from disability or age. Aluminum extrusions were chosen for their corrosion resistance and thermal and electrical conductivity, making them the best material for a product that is consistently exposed to soil and water while providing sufficient light.

“Each planter trough and grow light can be removed, replaced and reconfigured along any point in the chain that spans two horizontal rotational axis points, allowing more user freedom and control to choose how many plants to tend,” Lin commented. “The aluminum extrusion acts as a ground between the negative current running along one side of Veroto and the positive current running along the other side. The voltage is strong enough for effective grow lights while being low enough not to shock the user. Grow lights can run continuously with less maintenance. Veroto promotes ease of use regardless of the user’s mobility, bringing simple, comfortable gardening to everyone.

“The final design was modified for household or garden use with increased modularity,” noted the student. Rotating troughs are easily accessible, even for those using a wheelchair or who have other physical limitations. “The rotational unit provides access to all vegetation, regardless of a mobility disadvantage,” explained Thomas in her Design Intent statement, calling Veroto “Every Body’s Garden”.

The judges liked the design’s modularity and accessibility. “Aluminum extrusion gives the garden design versatility, ease of use and built-in adjustability and versatility features; a good use of aluminum extrusions,” noted judge Mark Butterfield. “This is practical and functional for the home gardener or small business.”

Kimiya Gheybparvar, of Carbondale, Illinois, a graduate design student at Southern Illinois University in Carbondale, Illinois, won a $1,000 Honorable Mention for her smart parking indicator pole design that visually indicates parking space availability using solar power in a unit made of 6063-T5 aluminum extrusions.

Her parking indicator system can be configured in the shape of a vertical pole or wall-mount module and is used to inform drivers whether a parking space is available, occupied or reserved. The indicator can be installed in indoor areas such as parking garages and commercial centers, and in outdoor areas such as on streets and in open parking lots.

Kimiya’s smart parking system uses an aluminum extrusion profile that is both structural and light carrying. The extrusion features precision side grooving, which provides easy mounting of LED strips on either side without screws or brackets. For exterior installations, the extrusion is mounted vertically via a pole body dedicated internal slot and is securely held in place without external fittings. The LED light strip is reflected off the pole surface to indicate a clear parking status using Green = Empty parking space; Red = Occupied parking space; and Blue = Accessible or reserved.

The indirect lighting indicator offers great visibility in daytime or nighttime, without glare. Outdoors, electric power to run the lights is obtained via a solar panel on the pole, providing an independent power source for lighting and sensors.

For indoor installations such as parking garage facilities at shopping malls, airports, stadiums, campuses, or office buildings, the module containing the aluminum extrusion is ceiling or wall-mounted above each parking space. LED light strips are placed in the extrusion’s side grooves, and the ultrasonic sensor is installed inside the module’s body, with only its sensing head protruding for accurate vehicle detection. The indoor system is powered from the building’s internal electric grid or from a central battery. This set-up enables quick, low-cost and accurate indoor installation for indoor environments.

Aluminum extrusion was selected for its light weight, excellent corrosion resistance, superior light reflectivity, customizable profile design and precise dimensional control. Extrusions offer this device practical heat dissipation to maintain LED performance. Kimiya notes that aluminum extrusion’s recyclability and reusability make it an eco-friendly solution, as well as offering cost savings and the best balance between performance, durability and production cost.

The system’s ESP32 board with onboard Wi-Fi enables each pole to transmit parking status information (vacant or occupied) wirelessly to an app or server, where it directs the presence of a vehicle via its ultrasonic sensor. The smart system enables real-time management and monitoring, offers accurate performance and easy set-up, and is highly scalable, flexible, and supports gradual smart city system integration, according to the student.

Unlike conventional market solutions that are only visible from specific angles, this product’s reflective light is highly visible from different angles and distances. Made from locally sourced extrusions and components, it is more cost effective and affordable than market alternatives without compromising potential full-scale smart system upgrades to smart infrastructure. Kimiya noted, “The Smart Parking Indicator Pole’s modern industrial design, with its clean, uncomplicated appearance and use of quality materials like aluminum extrusion, offers a product with both form and function suitable for modern urban settings.”

The competition judges agreed noting, “This is an energy-saving and handy device to help ease parking congestion. It’s so practical, and the outdoor indicator is self-sustaining, powered by a solar panel. It’s a simple and highly scalable extrusion design!”

# # #

About the ET Foundation

The Extrusion Technology for Aluminum Profiles Foundation has been established for charitable, scientific, and educational purposes to develop, promote, provide, and fund education and research related to aluminum extrusion processes and technologies. For more information, contact the ET Foundation mail@etfoundation.org or visit www.etfoundation.org, and follow news about ET ’27 on our LinkedIn page, and on Facebook and Twitter.

About AEC

The Aluminum Extruders Council (AEC) is a progressive trade association dedicated to advancing the effective use of aluminum extrusion in North America. AEC is committed to bringing comprehensive information about extrusion's characteristics, applications, environmental benefits, design and technology to users, product designers, engineers, and the academic community. Further, AEC is focused on enhancing the ability of its members to meet the emerging demands of the market through sharing knowledge and best practices. For more information, visit www.aec.org and follow AEC on Facebook, LinkedIn, and Twitter.